How to customize T-slot aluminum profile

Date: 2025-10-30Views: 366

How to customize T-slot aluminum profile? First, we should understand what T-slot aluminum profiles are, what the customization process is like, what preparations are needed, and how to avoid some wrong steps. Shenghai Aluminum will provide you with specific answers.

What is T-slot aluminum profile?

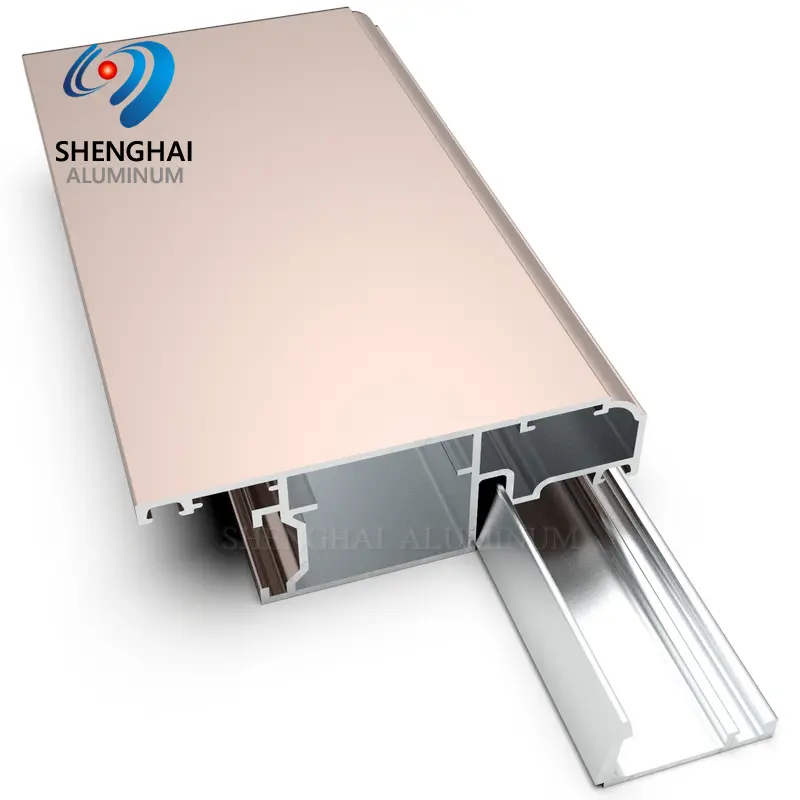

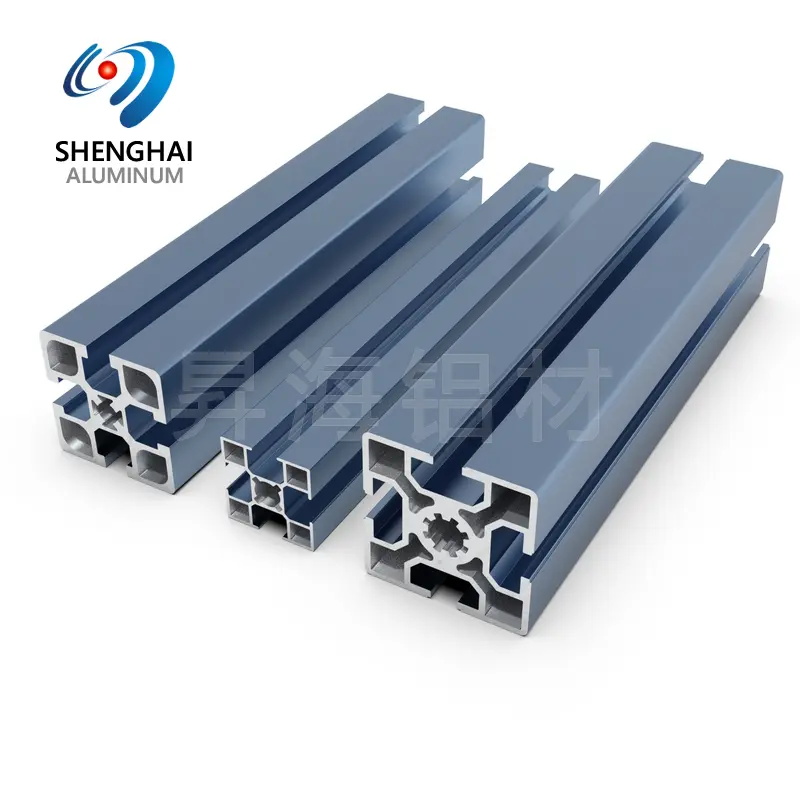

From the English words, it can be seen that it should have a T-shaped feature. In fact, T-slot aluminum profile is a long strip of aluminum profile extruded by machines. Its most distinctive feature is the T-shaped groove. It is also because of this groove that T-slot aluminum profile has unique functional characteristics. It can be easily fixed with various parts such as T-bolts, nuts, L-shaped connectors and straight connectors, allowing the aluminum profiles to form a multi-shaped and sturdy DIY aluminum profile frame.

What are the advantages of T-slot aluminum profiles?

They can be DIY-shaped

Due to the special modular structure of T-slot aluminum profiles, many types of products can be DIY designed, such as cabinets, wardrobes, tables, mirrors and picture frames. They have the characteristics of durability, beauty and no formaldehyde, and are very suitable for home use scenarios.

Simple and quick installation

The structure is simple and suitable for ordinary people to install. It only takes half an hour to install an aluminum profile table, which is very suitable for DIY enthusiasts.

Can be adapted for modification

It can be modified at any time to meet constantly changing demands. When you need to add a drawer to a finished table, you can do so without the cumbersome operations like cutting and drilling that are required for wooden tables. Therefore, the ability to meet constantly changing demands is also an advantage of T-slot aluminum profiles.

Lightweight

Have you ever been frustrated by not being able to lift your own wardrobe or table? Because wardrobes and tables need to balance both aesthetics and load-bearing capacity, they are usually made of wood or steel and designed to be quite heavy to maintain their load-bearing function. However, T-slot aluminum profiles are different. They are inherently beautiful and have excellent tensile strength, and they are much lighter than other materials. We believe that aluminum profile materials will offer you a unique experience.

Customized T-slot aluminum profile production process

After understanding the definition and advantages of T-slot aluminum profiles, it's time to choose the aluminum profile. We can select a suitable aluminum profile manufacturer to customize the aluminum profile. So, what is the process of customizing T-slot aluminum profiles? Shenghai Aluminum will introduce the following process steps.

1.Solution Confirmation

Customer demand analysis involves confirming the application scenarios of T-slot aluminum profiles, such as cabinets, wardrobes, tables, and other industrial equipment, as well as the aluminum alloy grade—since the type of grade affects price and load-bearing requirements—and the surface treatment method, with our commonly used ones including powder coating, electrophoretic coating, and anodizing. Additionally, it requires confirming the thickness and length, because only by confirming specific size information can we carry out 3D modeling and drawing design.

2. Designing the Mold

Due to the complex shape of the T-slot, the required mold needs to undergo special treatment. It will be extruded in a multi-cavity and multi-flow form. The mold design will take several days as there are still operations such as mold testing and polishing to be done later.

3. Casting

After selecting the appropriate aluminum alloy grade, we can melt the aluminum ingots. By adding the required metal elements according to the alloy grade and performing a series of impurity and gas removal operations, we can then proceed with cooling and casting, thereby generating the desired aluminum rods.

4. Extrusion

Before extrusion, the mold and aluminum bar need to be heated. Moreover, the heating of the aluminum bar also requires a cooling and heat preservation process as well as quenching. After these steps are completed, the T-slot aluminum profiles can be extruded. During the extrusion process, uniform and steady extrusion is necessary to produce aluminum profiles with uniform and aesthetically pleasing shapes.

5. Straightening and Cutting

The extruded aluminum profiles cannot be packaged immediately. They need to undergo straightening and cutting processes, and the extruded products that do not meet the standards should be inspected to ensure production quality and meet customer requirements.

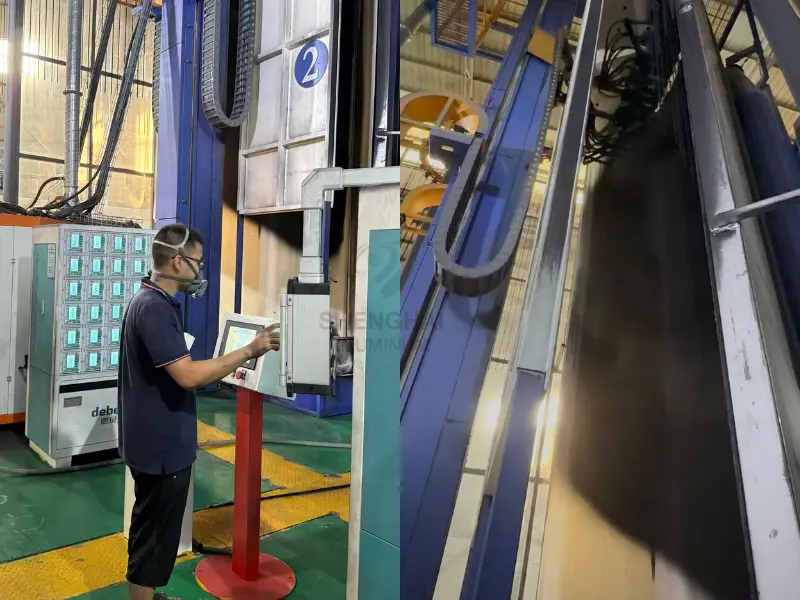

6. Surface Treatment

The most commonly used surface treatment method for us is powder coating. Once the parameters are determined, we can carry out the coating process. Remember to wear a mask during the process to prevent the powder from entering your mouth and nose, which could cause harm to your health.

7. Packaging

We use semi-automatic packaging methods. Our aluminium profiles need to be bundled up neatly and then sent to the packaging machine for film sealing to protect the surface of the aluminium profiles.

Why choose Shenghai Aluminium for custom T-slot aluminium profiles?

Shenghai is a manufacturer with 15 years of experience in aluminium extrusion products, including custom T-slot aluminium profile services, and is in a leading position in the industry. Therefore, we are confident that we can provide you with one-stop aluminium extrusion services and produce reliable products.