Which will be cheaper in 2025, aluminum profiles or steel?

Date: 2025-09-24Views: 355

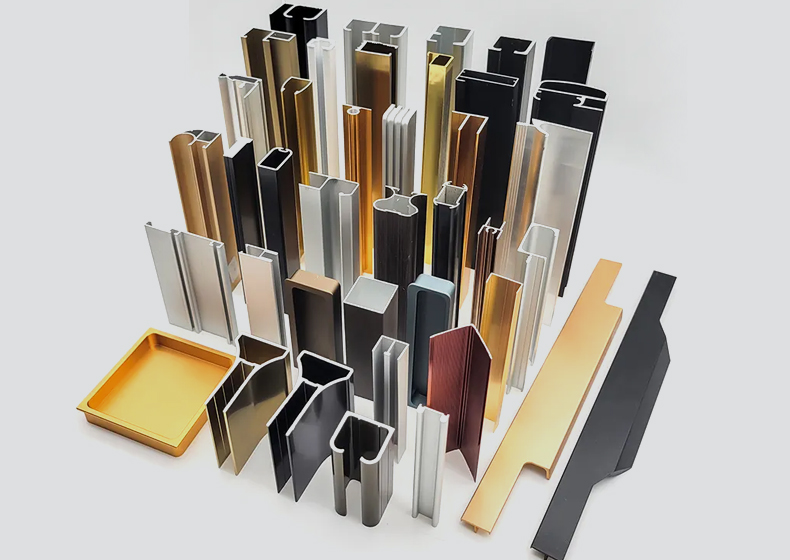

This is an article about choosing between aluminum profiles and steel. It mainly talks about which is cheaper, aluminum profiles or steel. It introduces the differences and advantages of the two from the perspectives of raw materials, processing, cost, maintenance, etc., so as to help you choose the material that meets your needs and expectations. I hope it can help those in need.

Raw Materials

The raw materials for aluminum profiles are more expensive than steel. The price of aluminum ingots (approximately 20,000 yuan/ton) is higher than that of ordinary steel (approximately 5,000 yuan/ton). However, the price of high-strength aluminum alloys (such as 7075) is close to that of specialty steel.

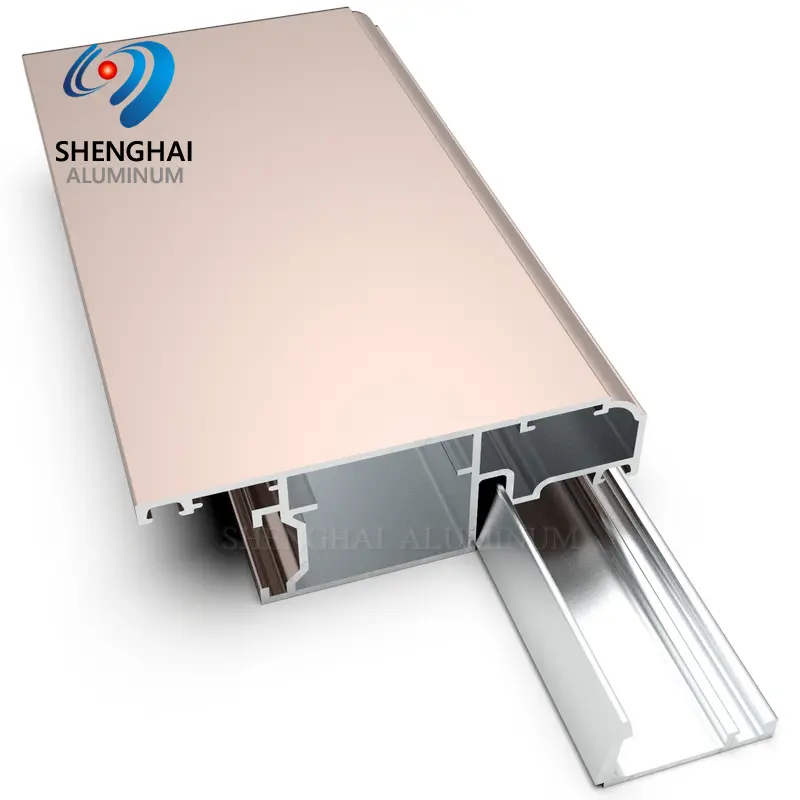

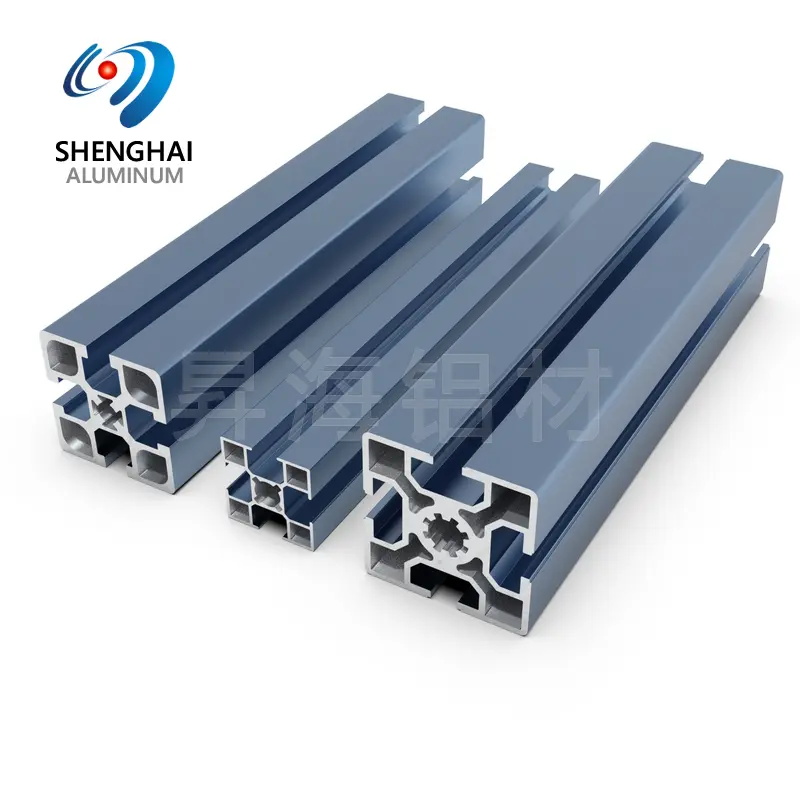

Processing Costs

Aluminum profiles are primarily extruded. Compared to steel rolling, the energy consumption is only one-third of that of steel, and the processing efficiency is much higher than that of steel. Therefore, aluminum profiles are more suitable for high-end customization needs. Overall cost is similar between the two.

Transportation Costs

Due to the low density of aluminum profiles, they are lighter. In terms of volume, steel is three times the weight of aluminum profiles of the same volume. Furthermore, steel requires additional reinforcement during transportation, which also represents an additional cost. Therefore, in terms of transportation costs, aluminum profiles can save 50%.

Maintenance Cost

Aluminum extrusions are renowned for their corrosion resistance and high chemical stability. Therefore, they require no corrosion protection treatment for extended periods of time. Steel, on the other hand, requires anti-corrosion spraying every few years, at a cost of up to 10% of the original cost. Therefore, aluminum extrusions offer a significant advantage in this regard.

Low Recycling Cost

Aluminum extrusions have a recycling rate of over 95%, and the energy consumption of recycled aluminum is only 5% of that of virgin aluminum (approximately 600 kWh/ton), resulting in a low recycling cost (approximately 80% of the original aluminum price). Steel has a recycling rate of over 90%, and the energy consumption of recycled steel is only 10% of that of virgin steel (approximately 150 kWh/ton), but scrap steel prices fluctuate significantly (influenced by iron ore prices).

Choosing Between the Two

When to Prefer Aluminum Extrusions: When the environment requires lightweight, corrosion resistance, customizability, and long-term use, aluminum extrusions are significantly cheaper than steel over the entire lifecycle, making aluminum a clear choice. Scenario for steel preference: When the environment requires high load-bearing capacity and short service life, steel can be chosen.