What Is The Quenching Process Of Aluminum Profiles Like

Date: 2025-10-22Views: 388

The quenching process of aluminum profiles is an important procedure in the aluminum industry. So, how does it work? Shenghai Aluminum will introduce to you its principle, steps, applications, and precautions, etc.

Principle

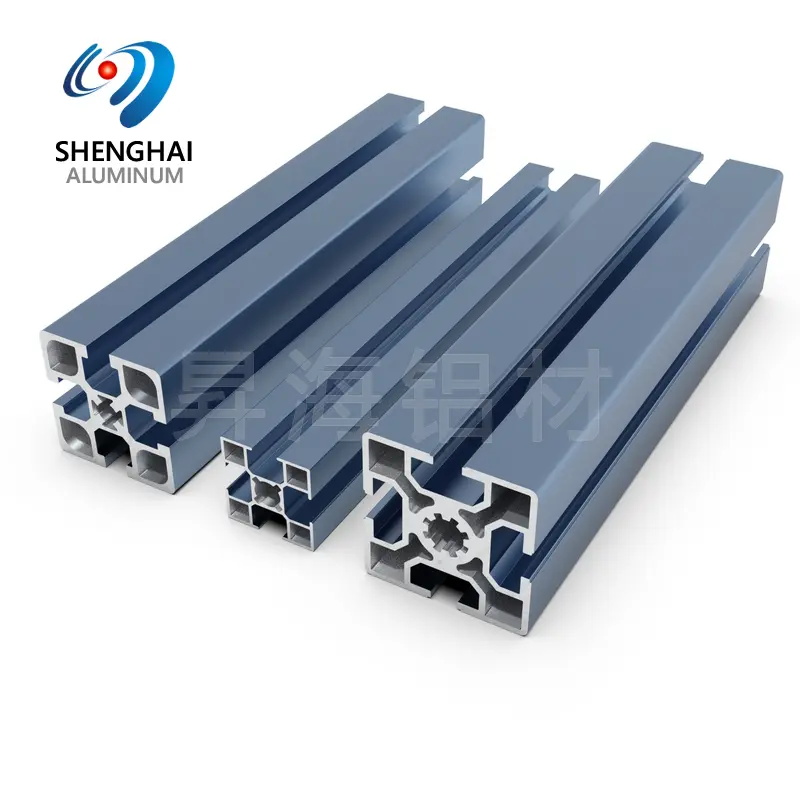

Quenching treatment of aluminum profiles is an important production process in the production of aluminum profiles and a key link in the heat treatment process. Aluminum profiles that have undergone quenching treatment can enhance their strength and hardness and increase their compressive resistance.

Why is quenching necessary for aluminum profiles?

1. From a physical perspective, it mainly increases strength and hardness. Aluminum profiles that have undergone quenching treatment can significantly enhance their strength and hardness.

2.From the perspective of elemental composition, since alloying elements such as Mg and Si in aluminum profiles tend to form unstable phases at high temperatures, this can easily weaken the solid solution strengthening effect, potentially leading to a decrease in tensile strength; a reduction in plasticity and elongation; a decline in corrosion resistance, with dark spots likely to appear on the surface during oxidation; and cracking of the profiles, resulting in a loss of surface aesthetics. However, quenching, through rapid cooling (such as air or water cooling), "freezes" the supersaturated solid solution at high temperatures, preventing the premature precipitation of alloying elements during the cooling process, thereby maintaining the strengthening potential of the material. This helps stabilize the alloy's elements and prevent precipitation.

What are the general steps of quenching?

1. Pretreatment stage

2. Quenching heating stage

3. Quenching cooling stage

4. Aging treatment stage

What should be noted in the process:

1. For industrial aluminum profiles with severe bending and twisting, Shenghai Aluminum will perform pre-straightening treatment before quenching. Special straightening machines will be used to straighten them to facilitate subsequent operations.

2. When quenching in a vertical hot air circulation quenching furnace, the front part of the aluminum profile should be placed upwards. For some thinner aluminum profiles, such as those no greater than 3mm and the tail end of profiles that have undergone secondary extrusion, they should be placed with the tail end upwards.

3. Each step must be strictly followed. Before loading the aluminum profiles into the quenching furnace, they must be tied with aluminum wire with appropriate force. Do not tie them too tightly. The larger sections of variable cross-section industrial aluminum profiles should not be placed closely together to avoid affecting the circulation of hot air and causing uneven heating.

4. Industrial aluminum profiles of adjacent specifications can be quenched in the same furnace, but the time must be reasonable.

5. The furnace temperature before loading should be close to the heat treatment heating temperature. It is not allowed to load the profiles when the furnace temperature is higher than the specified temperature.

6. To ensure uniform heating, the heating time during quenching should be controlled. The heating time during quenching is generally 30-40 minutes.

7. The water temperature for quenching industrial aluminum profiles is generally 10-35℃. For profiles with a thickness of 60mm or more, as well as those with complex shapes, large differences in wall thickness, variable cross-section profiles, the quenching water temperature can be appropriately increased, generally 30-50℃.

What are the differences between air cooling and water cooling quenching for aluminum alloy profiles?

Quenching of aluminum alloy is defined as a process where the material is rapidly cooled from a high temperature to a low temperature. For instance, quenching a steel knife in water makes the blade sharper. Similarly, for aluminum profiles, quenching can be done through water cooling or air cooling.

Aluminum profiles of building material 6063 are generally quenched by air cooling. After the quenched profiles are placed in the aging furnace for a certain period of time, the internal crystals of the aluminum profiles are rearranged, and the mechanical strength is significantly improved. Among all metal alloys, only aluminum alloys have an aging state.

The forming temperature of aluminum alloy extruded profiles is around 460 to 500 degrees. Generally, the temperature after quenching is required to be 200 degrees. Through high-temperature extrusion forming, after solid solution heat treatment (quenching), the artificial aging state is air-cooled, which is what we commonly call T5.

The cooling process through high-temperature extrusion molding and then entering the artificial aging state is water cooling, which is what we commonly refer to as the T6 state.

As the saying goes, T5 is air-cooled after extrusion, while T6 is water-cooled after extrusion. The hardness will increase after water quenching. It's that simple. However, if aluminum profiles need to be bent, it's better not to use the T6 state.

Application

We all know that aluminum profiles have advantages such as high strength, corrosion resistance and lightweight after quenching. Which products in daily life need quenching?

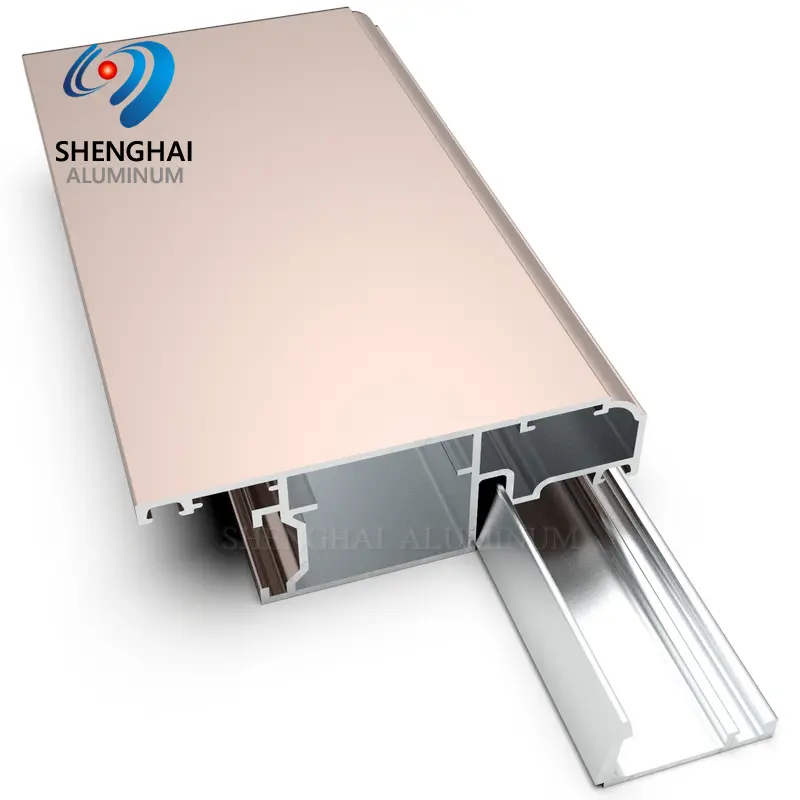

The framework of curtain walls

The framework of the curtain walls we usually see on high-rise buildings is made of quenched aluminum profiles. Due to long-term exposure to the sun and rain, this kind of framework requires anti-corrosion aluminum profiles, with the alloy type being 6063-T5 (air-cooled quenched).

Aluminum alloy bicycle frames

Steel materials do not necessarily need to be quenched, but the materials of aluminum alloy bicycle frames must be quenched before use, especially for racing road bikes, whose frames are usually very thin. This is because it involves the personal safety of the user, and thus has higher requirements for strength.

Kitchen cabinets

Due to the relatively humid environment in the kitchen, materials with more stable chemical properties are also required. Quenched aluminum profiles are a good choice.

Shenghai Aluminium has 15 years of experience in aluminium profile production. We strive to make every product perfect and serve every customer well. Our production equipment and technology have now been perfected, and we can provide a one-stop aluminium profile extrusion solution, including aluminium profile quenching processes. We believe we can solve any problems you have regarding aluminium profiles. For custom aluminium profiles, please contact us.