What is an aluminum hollow profile

Date: 2025-11-24Views: 284

An aluminum hollow profile is made by extruding aluminum. It is a common aluminum material used in daily life and is also part of aluminum profiles. Common examples of aluminum hollow profiles include aluminum door frames, aluminum window frames, aluminum furniture, aluminum heat sink, industrial aluminum profiles, car frames, and so on.

The basic properties of aluminum hollow profile

hollow aluminum profiles have the characteristics of light weight, high strength, corrosion resistance, durability, environmental friendliness and safety. Therefore, they can replace many materials, such as commonly used wooden materials, PVC materials and steel materials. As of 2025, aluminum hollow profiles still occupy the majority of the market share.

The difference between aluminum hollow profile and solid aluminum profile

Appearance

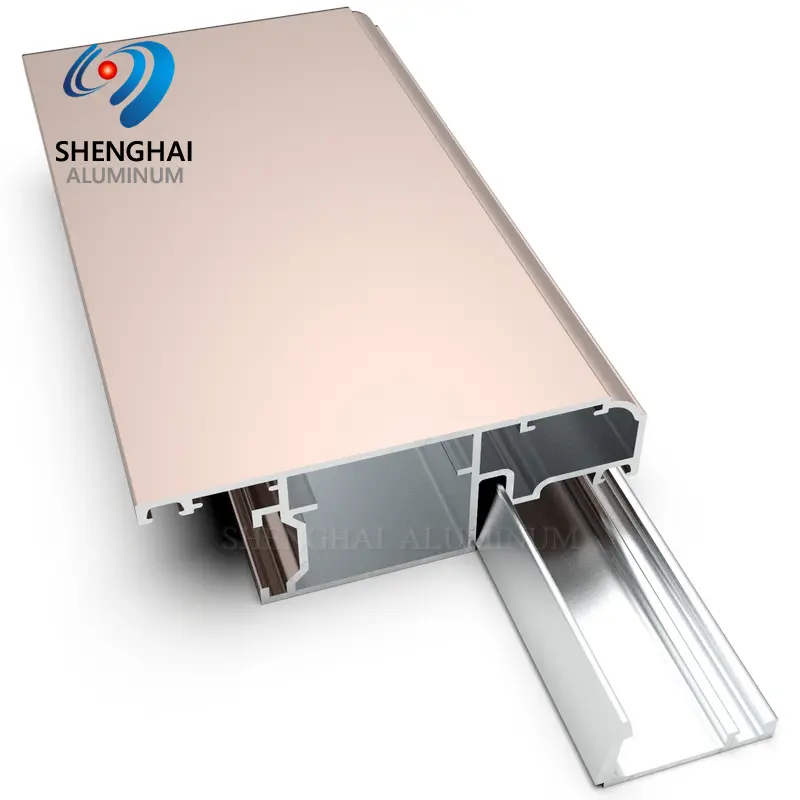

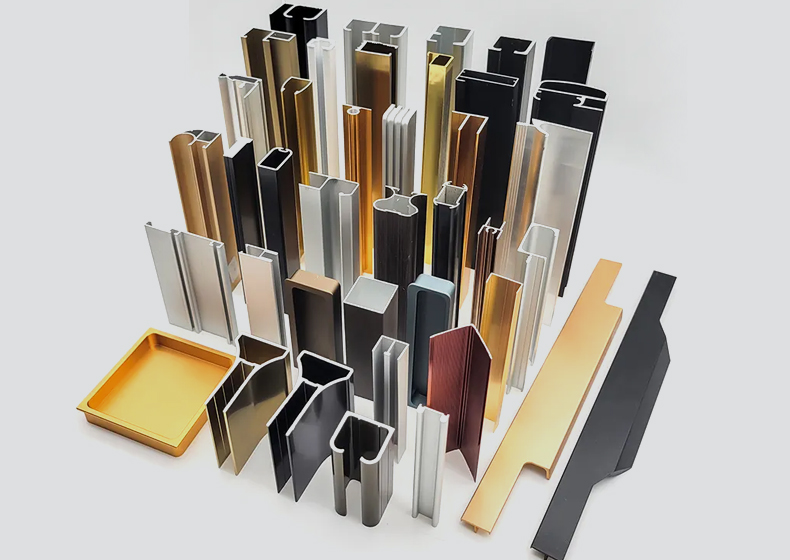

Aluminum hollow profile: From its appearance, it can be seen that the interior of the hollow aluminum profile has a cavity structure. Moreover, it comes in a wide range of colors and various surface treatment options, giving it a three-dimensional appearance and a pleasing look.

Solid aluminum profiles: The exterior is relatively simple, basically consisting of a solid strip-like structure, giving an impression of being thick and substantial.

Quality

Hollow aluminum profiles: Each layer of the hollow aluminum profiles is very thin, and the cavity has a large space. Combining with the advantages of aluminum alloy itself, hollow aluminum profiles have the advantages of being lightweight and sturdy.

Solid aluminum profiles: Solid profiles are heavier per unit length because they have no internal cavity structure. Therefore, more materials are needed for filling, resulting in a heavier weight.

Price

Hollow aluminum profiles: For the same length of aluminum profiles, hollow aluminum profiles use less material. Therefore, in terms of cost, hollow aluminum profiles are more cost-effective.

Solid aluminum profiles: It uses much more material than hollow aluminum profiles, and the price also increases accordingly.

Processing technology

Hollow aluminum profiles: The molds used for these profiles also have a multi-chamber structure, which makes the extrusion process more complex. Due to the multi-chamber structure of the hollow aluminum profiles, the surface treatment is more difficult and requires more time.

Solid aluminum profiles: The mold structure is simpler compared to other types, so the mold design can be completed more quickly. The extrusion speed of solid aluminum profiles is usually faster than that of hollow aluminum profiles. During surface treatment, because it lacks a multi-cavity structure, making the treatment process less difficult.

What types of aluminum hollow profile are there?

Aluminum door profiles: Aluminum door profiles include aluminum folding door profiles, aluminum bi-folding door profiles, aluminum sliding door profiles, and so on.

Aluminum window profiles: Aluminum window profiles include aluminum folding window profiles, aluminum bi-folding window profiles, aluminum sliding window profiles, and so on.

Curtain wall: The high-strength frame of the skylight is also made of hollow aluminum profiles. This is because the environment where the skylight is located mostly has factors such as ultraviolet rays and acid rain, as well as the influence of strong winds at high altitudes. Therefore, the material for the skylight is generally made of high-strength 6063-T5/T6 alloy, and the surface treatment usually focuses on weather resistance.

Heat sink: The aluminum hollow profile is highly suitable for use as a heat sink because it possesses excellent heat dissipation properties, light weight, corrosion resistance, durability, and cost-effectiveness, among other advantages.

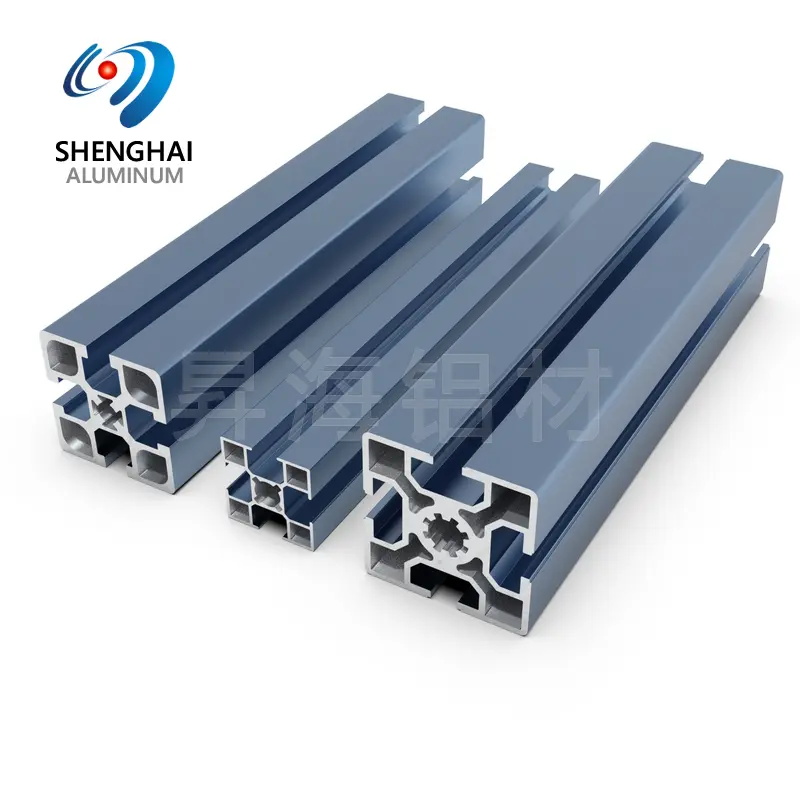

Industrial aluminum profiles: Hollow aluminum profiles are also commonly used in industrial applications, just like the aluminum profiles we use for DIY projects, such as DIY aluminum cabinets, DIY aluminum wardrobes, DIY aluminum tables, DIY aluminum photo frames, and so on.

The extrusion process of aluminum hollow profile

The extrusion of hollow aluminum profiles all follow a set of steps, including aluminum rod processing and heating, mold heating, extrusion, straightening, cutting, aging treatment, surface treatment, etc.

Unlike the rolling process of aluminum profiles, although aluminum extrusion cannot be mass-produced in the same way as rolling, it can extrude aluminum profiles with more complex cross-sections, which is a limitation of rolling.

Unlike the drawing process of aluminum profiles, aluminum extrusion has extremely high precision. The precision of drawing aluminum profiles is even higher. However, when comparing the costs of molds, the molds for aluminum extrusion can save several times the cost.

Unlike the forging of aluminum profiles, the strength of aluminum extrusion is not as high as that of forging. However, extruded aluminum can be sufficiently applied in various aspects of daily life. Forging aluminum is more suitable for high-end fields such as aerospace parts, etc. The cost of extruded aluminum is much lower than that of forging aluminum, and the extruded aluminum profiles have a more complex and diverse appearance.

Select an aluminum hollow profile supplier

In China, there is a reliable supplier - Shenghai Aluminum. It is a combination of a manufacturer and an international trader. Shenghai Aluminum has 15 years of experience in the production and manufacturing of aluminum hollow profiles and can provide customized services for hollow aluminum profile. It has served countless customers and has received numerous positive reviews. At any time and in any country, we can provide you with a one-stop aluminum extrusion solution.