What Is Aluminum Extrusion

Date: 2025-10-13Views: 422

What is aluminum extrusion? I believe everyone has this question. We can understand it from its principle, classification, advantages, steps, applications, and how to choose, etc. I believe it can solve this confusion for everyone.

Principle

The principle of aluminum extrusion is that the aluminum alloy material is heated to the required temperature, reaching a state where it can be freely controlled. At this point, pressure is applied to deform the aluminum billet inside the mold, and finally, it becomes an aluminum extrusion product with a specific cross-section.

The Steps Of Aluminum Extrusion

1. Preparation Of Raw Materials

Aluminum rods are usually used as raw materials. The aluminum alloy grade, such as 6061, 6063, etc., should be determined according to the required product. After selection, we also need to clean them to remove impurities.

2. Heating

Before extrusion, the material should be heated to around 500℃ to ensure smooth extrusion into the corresponding shape. The temperature should not be too high, otherwise it will cause the aluminum to become too soft.

3. Preparing The Mold

We at Shenghai can customize molds. The molds we produce have high precision and strength. During the extrusion process, the molds also need to be heated.

4. Start Extruding

Put the heated material into the extruder. The extrusion process should maintain a uniform speed to ensure the uniform flow of the aluminum material and produce a good product.

5. Cooling And Straightening

The extruded profiles should be cooled immediately after extrusion to prevent excessive deformation. After cooling, there will inevitably be slight deformations, so straightening operations are necessary.

6. Cutting And Surface Treatment

Cut into the desired shape and then carry out surface treatment such as anodizing or powder coating.

7. Packaging Inspection

Conduct size measurement, performance testing and appearance inspection. Only when there are no issues, proceed with packaging.

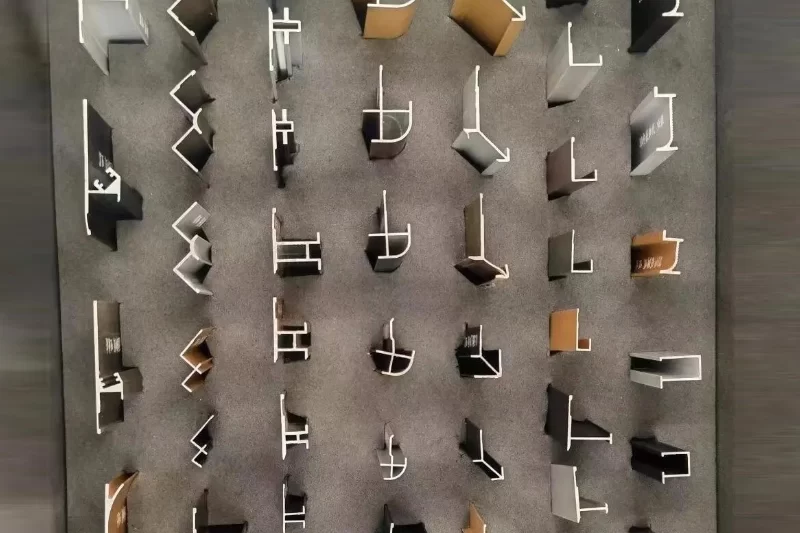

Classification Of Aluminum Extrusion

Forward extrusion: During production, the metal flow direction is the same as the movement direction of the punch. This is the most basic extrusion method and is widely used in practical applications. Aluminum profiles are mostly produced by forward extrusion.

Reverse extrusion: During production, the metal flow direction is opposite to the movement direction of the punch. This extrusion method can make the metal deformation more uniform, and the structure and performance of the product can also be improved better. It is often used in the processing of some aluminum materials with higher requirements for material performance.

Compound extrusion: During production, one part of the billet's metal flows in the same direction as the punch's movement, while the other part flows in the opposite direction. Compound extrusion combines the advantages of forward extrusion and backward extrusion, enabling the production of more complex-shaped and superior-performance aluminum products.

Radial extrusion: During production, the metal flow direction is at a 90-degree angle to the movement direction of the punch. It is mainly used to manufacture aluminum materials with special shapes or size requirements, such as thin-walled tubes and hollow profiles, and can meet the demands of specific fields.

The Advantages Of Aluminum Extrusion

In our daily life, the common aluminum profiles such as doors and windows, automotive parts, decorative strips for floor tiles and kitchen cabinets at home are basically produced through the aluminum extrusion process. So, what are the advantages of aluminum extrusion?

Since the products mentioned in the previous paragraph are all of rather complex shapes, the aluminum extrusion technology can easily complete the manufacturing process and has extremely high precision. Even if you measure with a high-precision ruler, there will be no error. This is because the molds are made of high-strength steel and basically do not deform, which will not affect the shape of the aluminum profiles. Therefore, high precision is an advantage of the aluminum extrusion process.

Extruded aluminum profiles have very high strength. After a series of processes, the product structure becomes very compact and orderly, capable of withstanding tremendous pressure. Therefore, the door frames of anti-theft windows and doors are very sturdy, and automotive parts can also maintain great load-bearing capacity.

Therefore, the advantages of aluminum extrusion can roughly be divided into high customization, high precision and high strength.

Product Applications

What products can be made from extruded aluminum? Generally, there are the following parts:

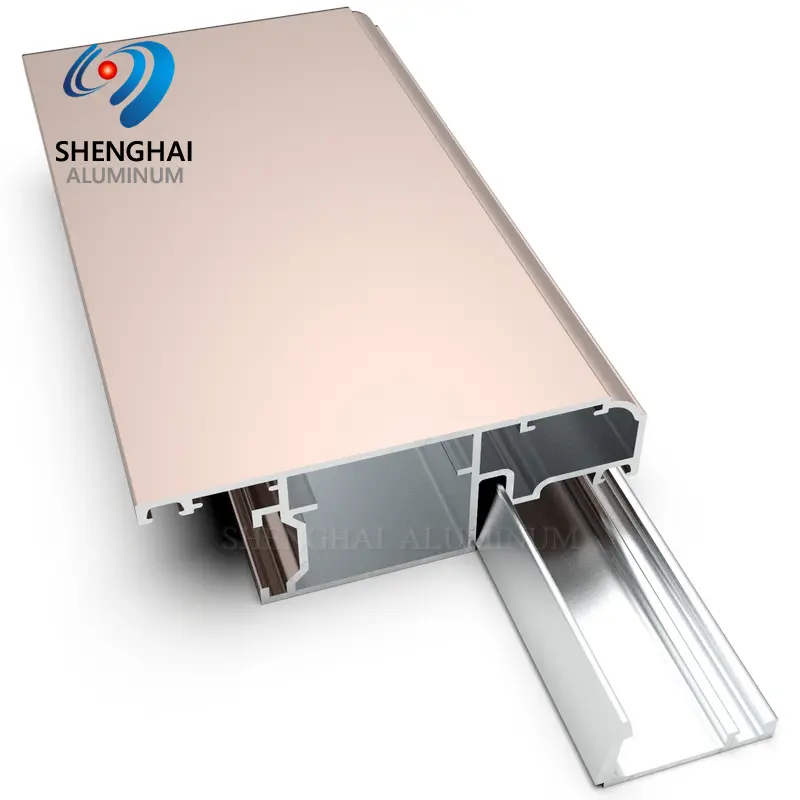

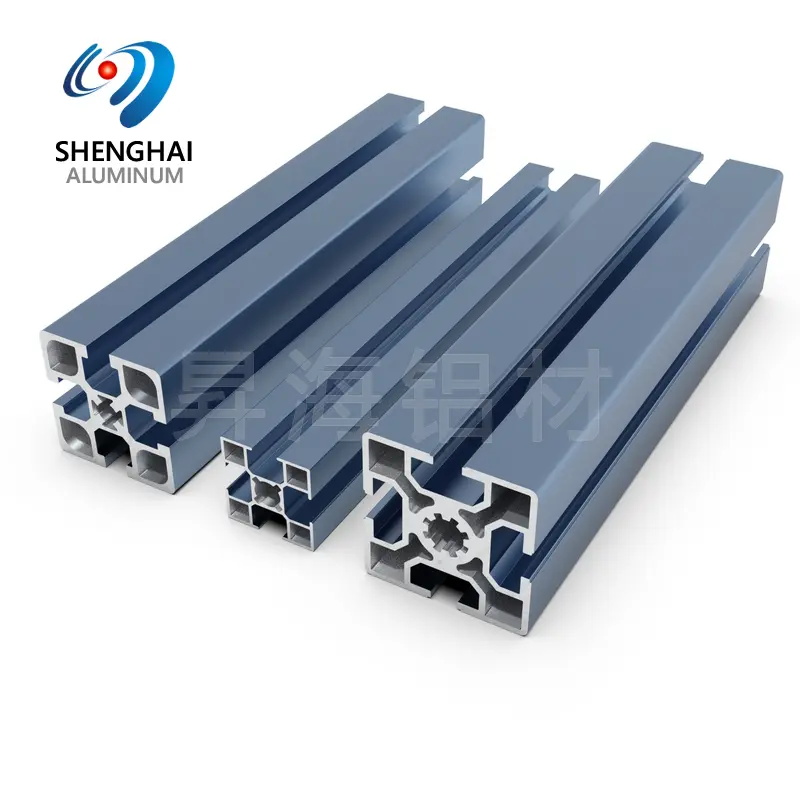

Aluminum Alloy Profiles

Our aluminum extrusion products in Shenghai mainly consist of aluminum alloy profiles, which have the largest customer base. They come in various shapes, including flat, convex, concave, and irregular forms. Common customer demands include aluminum doors and windows, aluminum trim strips, and kitchen cabinets, etc.

Aluminum Alloy Tubes

Their shapes are generally divided into round tubes, square tubes and rectangular tubes. Our products are often used for architectural decoration and home renovation.

Aluminum Alloy Rods

We usually extrude them into common cross-sectional shapes such as round, hexagonal and square, and apply them in electrical appliances and automobiles.

How To Choose Good Aluminum Extrusion products?

1. Surface Observation

the color of the aluminum extrusion product should be uniform without any local spots or cracks, and the surface should be relatively smooth.

2. Composition

This is a very important factor to consider when making a choice, as it can affect strength, hardness, and performance, etc. Therefore, it is essential to look at the composition. If it is pure aluminum, the strength will not be high. It is best to contain magnesium and silicon elements to ensure the strength of the aluminum extrusion product.

3. Dimensions

The dimensions must be precise; otherwise, misalignment will occur during installation.

4. Find the Right Manufacturer

China is a major producer of aluminum extrusion products in the world. Therefore, coming to China to find a supplier is the most appropriate choice. You need to consider whether they are a manufacturer, whether their products have quality certifications, whether they can provide customization services, their production capacity, and the delivery time, etc. Among them, Shenghai meets these requirements.

By now, you should have a clear understanding of what aluminum extrusion is. If you want to know more, feel free to contact us. We, Shenghai, are a manufacturer with 15 years of experience, capable of designing based on your drawings. With our ISO9001 certification, you can rest assured about the quality of our products. We can produce any aluminum extrusion products as long as you have the demand.