How to choose aluminum profile

Date: 2025-10-24Views: 409

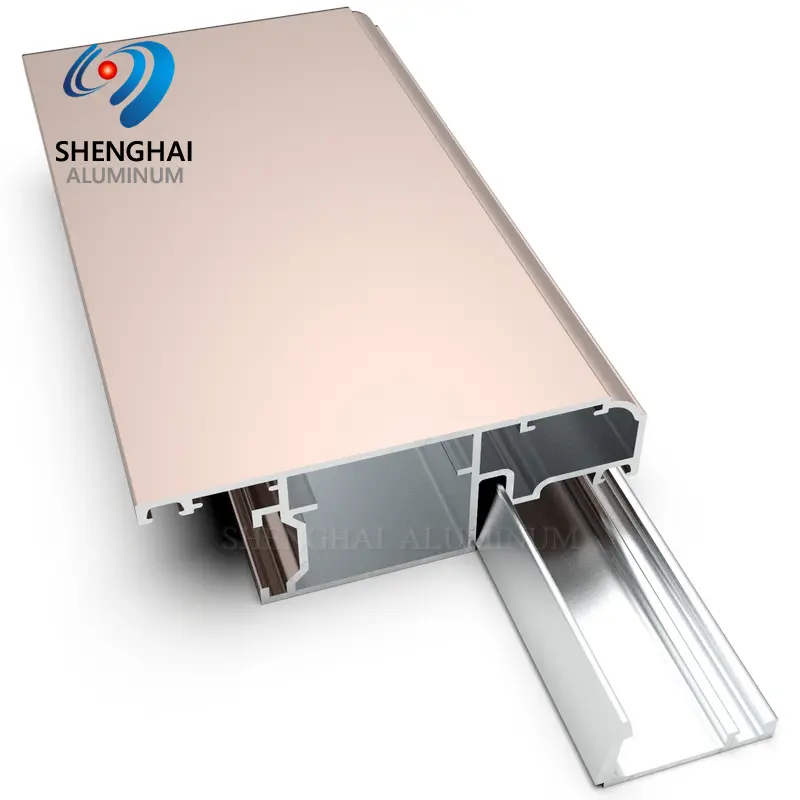

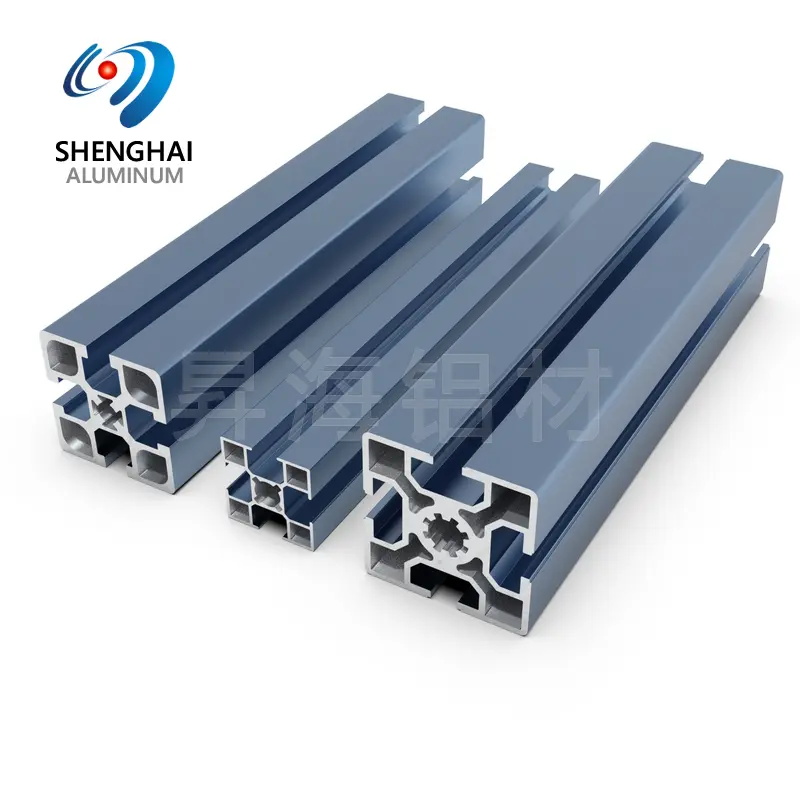

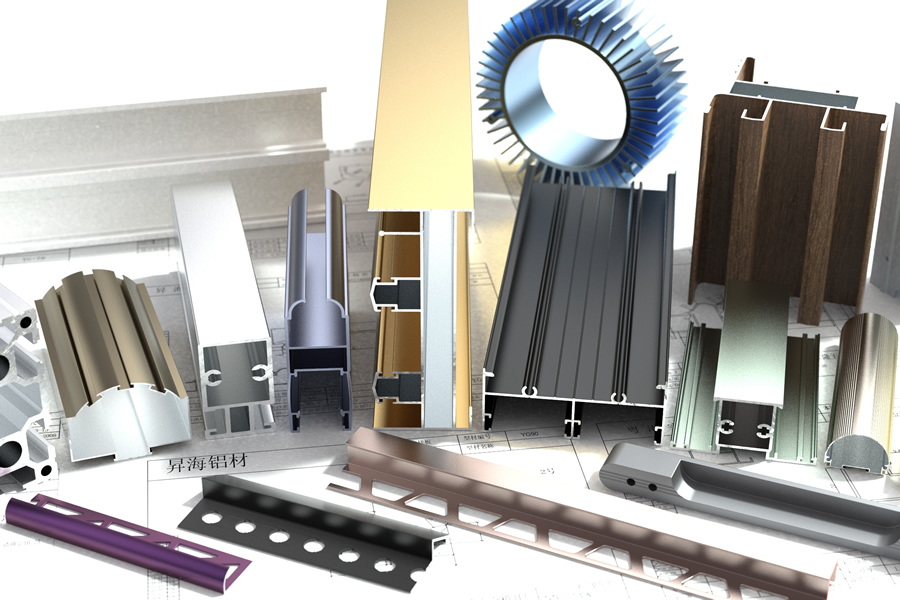

Aluminum profile are a type of metal material produced through specific techniques. They come in various shapes, and the shape of the aluminum profiles produced will differ depending on the mold used. When choosing aluminum profile, many manufacturers, traders, and distributors often need to consider many factors. Shenghai Aluminum will provide a detailed introduction on how to select aluminum profiles and solve various problems encountered.

Aluminum profiles are typically produced from aluminum rods using various methods such as extrusion, rolling, casting, forging, superplastic forming, and powder metallurgy. Extrusion is the most common and popular method, producing aluminum profiles for furniture, decorative purposes, baseboards, doors and windows. The following section details various aspects to consider when selecting aluminum profiles.

How to choose aluminum profile materials?

Why should we pay attention to material selection? Because incorrect material selection not only leads to cost waste and substandard product performance, but also may cause safety hazards in scenarios with strict safety requirements. Therefore, material selection is also a significant matter.

Common grade selection

Common grades and classifications include international standards (AA), Chinese national standards (GB), and European standards (EN). The following is the selection of grades based on international standards.

6063: Its main components are Al-Mg-Si, a magnesium-silicon alloy. Due to its excellent corrosion resistance, good surface treatment performance, and smooth and attractive appearance, it is often used to make window and door frames (folding doors and windows, sliding doors and windows, and swing doors and windows) and decorative materials (aluminum skirting boards, aluminum trim strips).

6061: Its main components are Al-Mg-Si-Cu (magnesium-silicon-copper alloy). It has balanced overall performance, and thus is often used to make aluminum cabinets and drawer slides.

5052: Its main component is Al-Mg (magnesium alloy), which has good corrosion resistance and ductility. Therefore, it is very suitable for making outdoor equipment such as barbecue grills, camping vehicles and car fuel tanks.

Choose based on the priority of performance

Choose based on the priority of performance

Strength: If strength is the priority, we can select 7075 (with extremely high strength), which can be used in aerospace and military equipment.

Corrosion resistance: If corrosion resistance is required, then 6061 (from the 6 series) can be chosen.

For higher requirements of lightweight, 6063-T5 is recommended.

Conductivity: For applications with requirements for conductivity, choose 1 series (1050) pure aluminum.

High-temperature resistance: For use in high-temperature environments, 2024, 6061 and 3004 grades can be selected.

Surface treatment: For those who have high aesthetic and color requirements, options such as 6063, 5052, 1050, etc. can be chosen.

Choose the ones with better cost performance based on cost

Commonly, the more cost-effective grades are 6063, 6061, 2003 and 5083.

Notes:

Pursuing low prices often leads to quality defects, such as excessive impurities and high levels of harmful substances. It is not the case that low prices always save money. If the corrosion resistance of aluminum profiles is poor, it will result in increased maintenance costs in the long run, making it not worth it. Therefore, it is necessary to choose a reliable supplier that can provide SGS reports.

The extrusion production process of aluminum profiles

The entire production process of aluminum profile is not simple, and the process for each processing method is also different. The following will introduce the extrusion process of aluminum profile, which generally includes aluminum bar preparation, aluminum bar heating, straightening, quenching and surface treatment, etc.

Preparation of aluminum rods

The materials transported back are not necessarily good and still need to be inspected, mainly for surface quality inspection. It can be seen from the surface that the surface of the aluminum rods is smooth, without bubbles or cracks, etc.

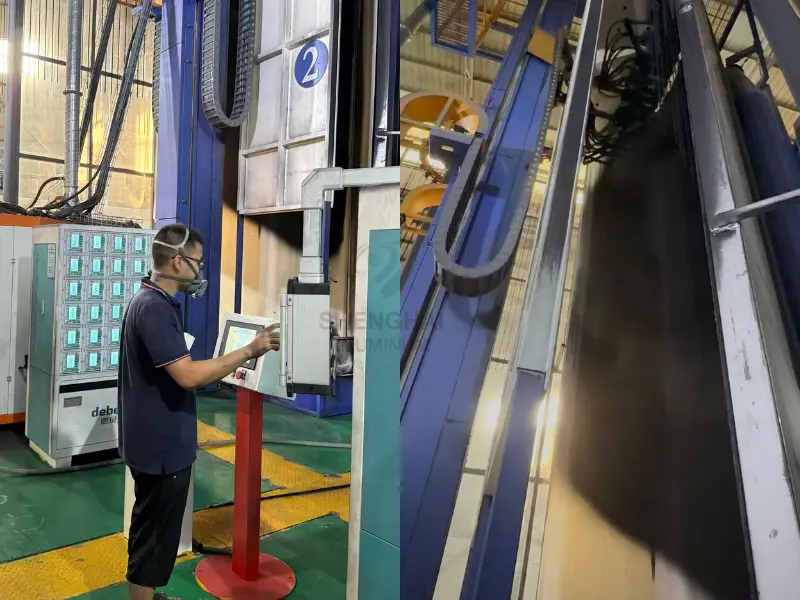

Heating of aluminum rods

Non-contact infrared sensors are used to detect the surface temperature of the aluminum rods. When operating, high-temperature resistant gloves and goggles must be worn because the aluminum liquid may splash. Safety comes first.

Aluminum profile straightening

The profiles must be cooled to below 50℃ before being placed in the straightening machine for straightening to avoid deformation caused by internal stress.

Aluminum profile quenching

Before quenching, the profiles need to be pre-straightened. After quenching, artificial aging treatment should be carried out. During the operation, precautions should also be taken against high-temperature hazards.

Surface treatment

In surface treatment, powder coating is widely used. Before the treatment, the surface needs to be cleaned because there are inevitably many impurities on the surface of profiles, which need to be removed. Besides removing impurities, the surface also needs to be wiped with deionized water to facilitate adsorption.

Choosing aluminum profiles supplier.

China is the country that produces the most aluminum, and Shenghai Aluminum is one of the top companies. With 15 years of production experience, it is the preferred choice for custom profiles, with quality guaranteed. Product certifications include ISO9001. There is no need to worry about the confusion in selection. Shenghai Aluminum will provide you with a one-stop solution and help you solve any problems related to aluminum profiles.

Why choose Shenghai Aluminum?

15 years of production experience

Products certified with ISO9001

OEM customization available

Guaranteed after-sales service

Seven production lines, strong production capacity