Don't know how to choose high-quality aluminum profiles?

Date: 2025-09-28Views: 450

When purchasing high-quality aluminum profiles, we often wonder what type to choose. Actually, there's a lot to learn about aluminum profiles. Below is some helpful information about aluminum profiles, hoping it will help you avoid wasting money.

1. Basic Properties of Aluminum

Aluminum, a silvery-white metal, is the most abundant metal element in Earth’s crust (~8.3% by mass). It forms a protective oxide film in moist air, enhancing corrosion resistance though it may dull over time when exposed. With a low relative density of 2.7 g/cm³, it is lightweight; it melts at 660.37°C and boils at 2327°C. Boasting high specific strength (excellent strength-to-weight ratio), good electrical conductivity (second only to silver and copper, ideal for high-voltage lines), and exceptional thermal conductivity (~3x iron’s, suited for radiators), it also excels in reflectivity (for mirrors/coatings) and oxidation resistance, reinforced by its oxide layer.

2. Types

2. Types

Profiles: high-quality aluminum profiles, aluminum tubes, aluminum bars, etc.

Sheets: Aluminum sheet, aluminum foil, aluminum strip (coil)

Castings: Aluminum castings, aluminum pellets

3. Commonly Used Grades

The first digit of the grade indicates the aluminum alloy series, the second digit indicates the modification of the original aluminum alloy, and the last two digits indicate the purity of the aluminum alloy within the same group.

1100:Used for parts requiring good formability and high corrosion resistance but not high strength. Examples include storage containers, thin sheet metal parts, deep-drawn concave vessels, heat exchangers, printing plates, nameplates, and reflective fixtures.

2011:A free-cutting alloy with good machinability and high strength, but poor corrosion resistance. Suitable for volume shafts, optical components, screw heads, screws, and other machined products requiring good machinability.

3003:It possesses the properties of 1xxx series alloys but offers higher strength than 1xxxx series alloys. Applications include kitchenware, food and chemical processing and storage equipment, tanks and cans for transporting liquid products, and various pressure vessels and piping for thin sheet metal processing.

4A01:High in silicon content, heat-resistant and wear-resistant, it is used in construction, machine parts, forging, and welding.

5052:The most representative alloy with medium strength (5083 is the highest), offering excellent corrosion resistance, weldability, and formability, particularly high fatigue strength and excellent seawater resistance. It is used in the manufacture of aircraft fuel tanks and pipelines, sheet metal parts for vehicles and ships, instrumentation, streetlight brackets, rivets, and hardware.

6061:A heat-treatable, corrosion-resistant alloy. T6 treatment yields very high strength, but weld strength is low, making it suitable for screws, ships, vehicles, and land structures.

6N01:A medium-strength alloy for extrusion, suitable for large, thin-walled profiles with complex shapes. It offers excellent corrosion resistance and weldability. It is suitable for vehicles, land structures, and ships.

6063:A representative alloy for extrusion, with lower strength than 6061 but excellent extrudability. It can be made into profiles with complex cross-sections. It offers excellent corrosion resistance and surface treatment properties. It is suitable for highway guardrails, vehicles, furniture, home appliances, and decorative items.

7072:Has a low electrode potential and is primarily used for corrosion-resistant coverings. It is also suitable for heat exchanger fins, air conditioner foil, and ultra-thin strip.

7075:One of the strongest aluminum alloys, it offers poor corrosion resistance. Covering with 7072 can improve its corrosion resistance, but at a higher cost. Suitable for aircraft, ski poles, thick plates, and forgings.

Material Selection Example:

For products requiring relatively high hardness and a rough brushed or coarse sanded surface, choose a 5000 series aluminum alloy, commonly used: 5052.

For products requiring high surface finish, free of sand holes and profile marks, choose a 6000 series aluminum alloy, commonly used: 6063/6061.

For products requiring low price and requiring tensile testing, choose a 2000 series pure aluminum alloy, commonly used: 2011.

For products requiring high strength and hardness and load-bearing structural use, choose a 7000 series aluminum alloy, commonly used: 7075.

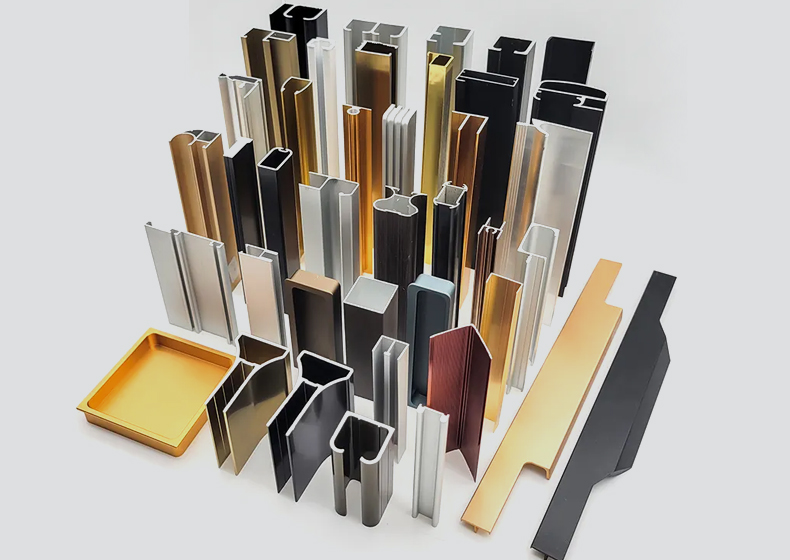

IV. Aluminum Surface Treatment

1. Anodizing after sandblasting or brushing

2. Electrophoretic painting

3. Electrostatic powder coating or fluorocarbon spraying after polishing

4. Electroplating after mirror polishing

5. Wood grain thermal transfer printing

6. Polymer PVC coating

V. High-Quality Aluminum Profiles

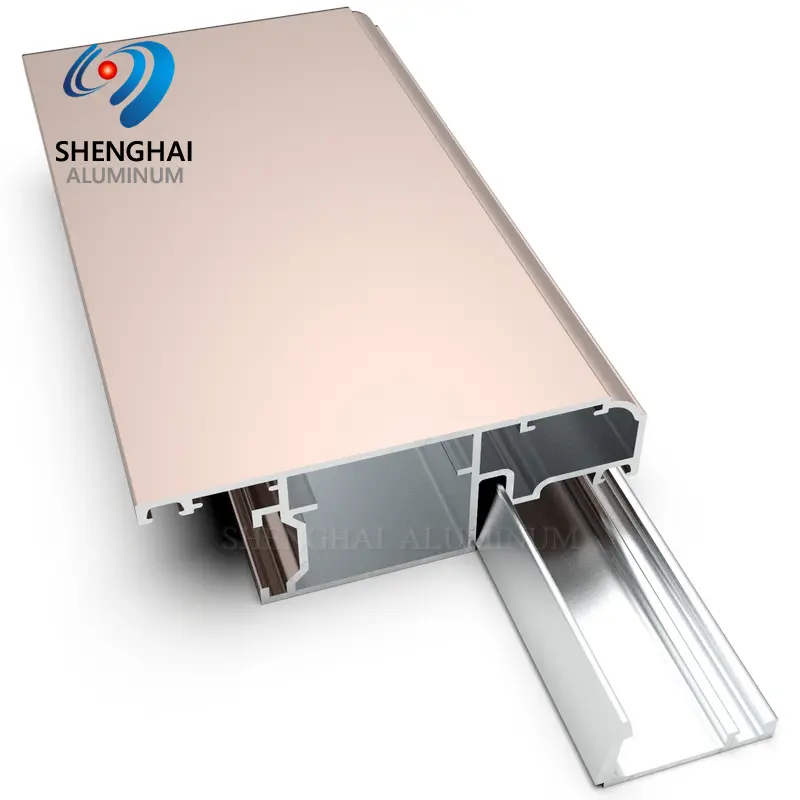

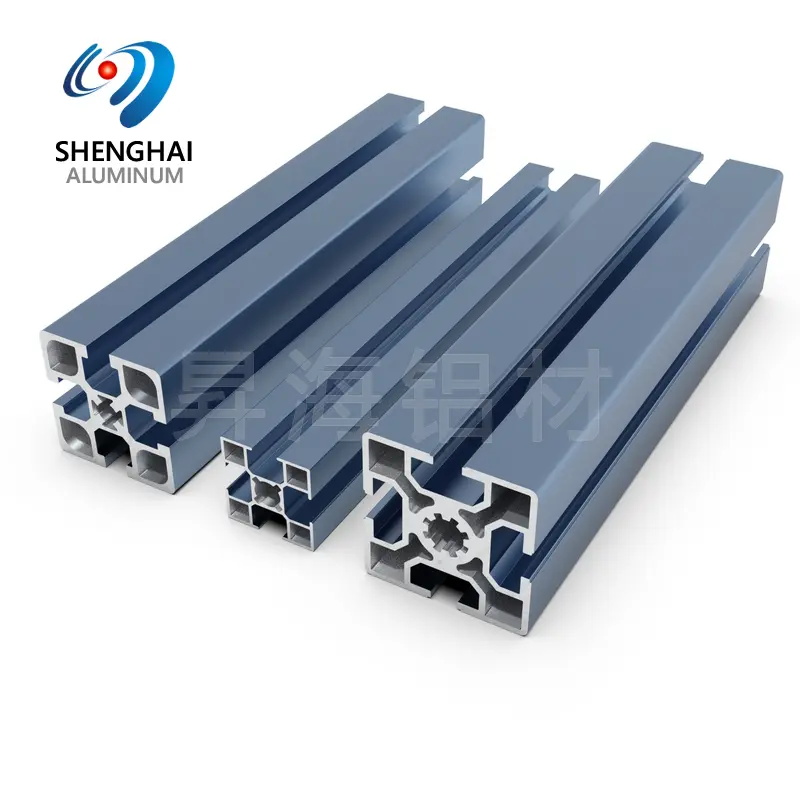

Aluminum profile are aluminum tubes made from aluminum rods by hot melting and extrusion to create various cross-sectional shapes. The molding process primarily includes five steps: melting, extrusion, cutting, CNC cleaning and cutting, surface pretreatment, and painting.

Titanium plating and electrophoresis are the most expensive, followed by wood grain thermal transfer, anodizing, and finally spray painting. Specific prices are subject to manufacturer's quotation.

The main applications of aluminum profiles are as follows:

1. Architectural aluminum profile (doors, windows, curtain walls)

2. Radiator aluminum profile

3. General industrial aluminum profiles: Primarily used in industrial manufacturing, such as automated machinery and frames, and can be customized with molds.

4. Rail vehicle structural aluminum alloy profiles: Primarily used in rail vehicle body construction.

5. Decorative aluminum profiles: Made into aluminum alloy frames for mounting various decorative paintings.

6. Exterior high-quality aluminum profiles: Primarily used in the home appliance and communications industries, such as portable hard drives, power banks, televisions, and monitors, for internal structure and exterior decoration.

VI. Aluminum Sheet

Thin Sheet (Aluminum Sheet): 0.15-2.0mm

Regular Sheet (Aluminum Sheet): 2.0-6.0mm

Medium Sheet (Aluminum Plate): 6.0-25.0mm

Thick Sheet (Aluminum Plate): 25-200mm

Extra Thick Sheet (200mm and above)

Single-layer Aluminum Sheet

Can be used for electronic product casings, home appliance casings, or internal thermal conductors.

The finished aluminum casing is completed through a three-step process: stretch forming using a metal stamping die, surface pretreatment, and coloring.

Polymer Film Aluminum Sheet

It features specific forming slope requirements, is non-stretchable, corrosion-resistant, highly weather-resistant, available in a variety of colors, and is easy to maintain.

Suitable for electronic product casings, home appliance casings, etc.

Aluminum-Plastic Composite Panel

This is a new material composed of surface-treated and painted aluminum sheet with a core layer of polyethylene and polypropylene plastics, processed and laminated through a series of processes.

It can be used for decorative applications such as curtain walls, interior and exterior walls, foyers, restaurants, shops, and conference rooms. It can also be used in the renovation of existing buildings, as counters, furniture surfaces, and the interior and exterior cladding of vehicles.

Honeycomb Aluminum Panels

Using a composite honeycomb structure, preformed box-shaped panels and back panels are hot-pressed together with an aluminum alloy honeycomb core.

It is suitable for building curtain wall decoration, ceilings, buses, trains, subways, and rail transit vehicles, commercial trucks and container truck bodies, shipboard structures, billboards, and interior decoration projects.

Aluminum components used for decorative product exteriors with high-strength surfaces are generally 0.4-0.8mm thick and are made from grades 6063/6061 or pure aluminum.

Aluminum components used for functional exteriors with bottom stretching and bent structures are generally 0.8-1.2mm thick and are made from harder grades such as 5052/7075 or specialized grades.

Aluminum parts used in electronic product housings require laser engraving of the oxide layer before conducting and grounding, as the anodized oxide layer is non-conductive.

VII. Aluminum Alloy Die-Casting

When designing aluminum alloy die-castings, minimize the use of beveled tops to prevent subsequent burr removal, which can be difficult.When designing aluminum alloy die-castings, also ensure uniform glue thickness and smooth glue flow. This can minimize problems such as poor appearance caused by molding and increased subsequent polishing and re-inspection.If a softer grade is chosen, structural strength must still be considered when designing load-bearing structures, as otherwise, they may break easily.Having said this, do you still have questions when choosing aluminum profiles?