Shenghai's solar aluminum alloy bracket can maintain excellent performance in extreme high temperature, high humidity or salt spray environments. After special treatment, the naturally formed oxide film on the surface of the aluminum alloy bracket can effectively prevent oxidation and greatly extend its service life.

Aluminum alloy itself is a completely recyclable material. Using aluminum alloy brackets can not only reduce resource waste, but also reduce secondary pollution. Compared with other metal materials, aluminum alloy can significantly reduce energy consumption during processing and is an environmentally friendly green building material.

High comprehensive cost performance

Although the initial purchase price of aluminum alloy brackets may be slightly higher than other metal materials, their long life, low maintenance cost and high durability mean that in the long run, aluminum alloy brackets provide a higher cost performance for solar power generation systems. Reduced maintenance frequency and reduced repair costs make it a cost-effective choice.

Our customers from all over the world:

| Parameter | Details |

|---|---|

| Material & Temper | Alloy 6063-T5, 6061-T6 We will never use aluminum scrap. |

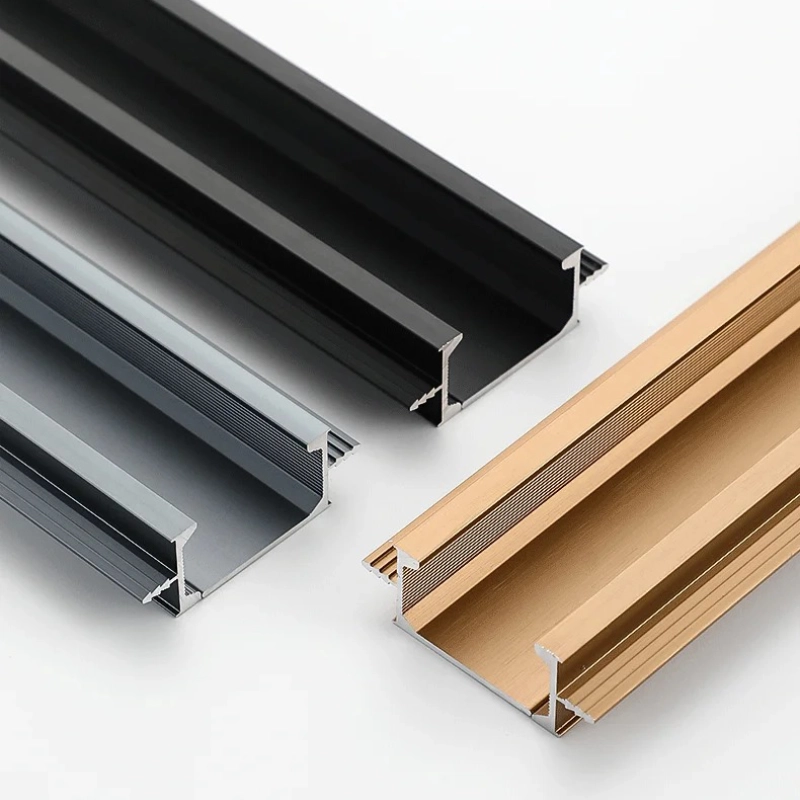

| Surface Treatment | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability Output | Output 1200 tons per month. |

| Profile Type | Sliding window and door profiles; Casement window and door profiles; Aluminum profiles for LED light; Tile Trim Aluminum profiles; Curtain wall profile; Aluminum heating insulation profiles; Round/Square General profiles; Aluminum heat sink; Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification | ISO9001-2008/ISO 9001:2008; GB/T28001-2001(including all the standard of OHSAS18001:1999); GB/T24001-2004/ISO 14001:2004; GMC. |

| Payment | T/T: 30% deposite, the balance will be paid before delivery; L/C: the balance irrevocable L/C at sight. |

| Delivery Time | 15 days production

If opening mould, plus 7-10 days |

| OEM | Available |