Aluminum profile powder coating process

Date: 2025-10-17Views: 484

The following is an introduction to the aluminum profile powder coating process, including its meaning, steps, and advantages, etc. It is hoped that it can be helpful to everyone.

Overview

The aluminum profile powder coating process is a systematic surface treatment technology that uses solid powder coatings as raw materials. Through electrostatic adsorption and thermal curing techniques, it forms a continuous and dense protective and decorative coating on the surface of aluminum profiles. This process endows aluminum profiles with excellent weather resistance, corrosion resistance, mechanical strength, and aesthetic appeal, making it an important technical means in the aluminum processing industry.

steps

Pass through the machine for grinding → Spray the upper row (vertical ones need to be drilled) → Clean the blank → Dry the blank → Electrostatic spraying→Curing and removal from the furnace→Surface inspection

1.Polishing:

Check if the material is clean, smooth and free of mechanical marks.

2.Spray the upper row:

Check the surface for scratches, particles, etc., and perform air-blowing and sanding.

3. Cleaning:

1) Objective: The cleaning agent is used for degreasing, that is, removing oil.

2) Pre-degreasing → Main degreasing → Water washing 1 → Water washing 2 → Water washing 3 → Chromium-free passivation

Water washing 4

3) Chromium-free passivation: Enhance the corrosion resistance of the metal substrate and the adhesion of subsequent coating surfaces, prevent surface powdering, achieve true cleanliness and environmental friendliness, and ensure that the product meets environmental protection requirements(pH value is 6.5-8, with 7 being the optimal value).

4.Powder coating:

Control temperature, speed and uniformity.

5. Curing:

Cure at a high temperature of 180-240℃ for 15-25 minutes. Bake the powder at high temperature to melt it and make it adhere tightly to the surface of the workpiece, achieving a smooth and hard curing and protective effect.

6. Inspection:

Inspect the surface for smoothness and evenness.

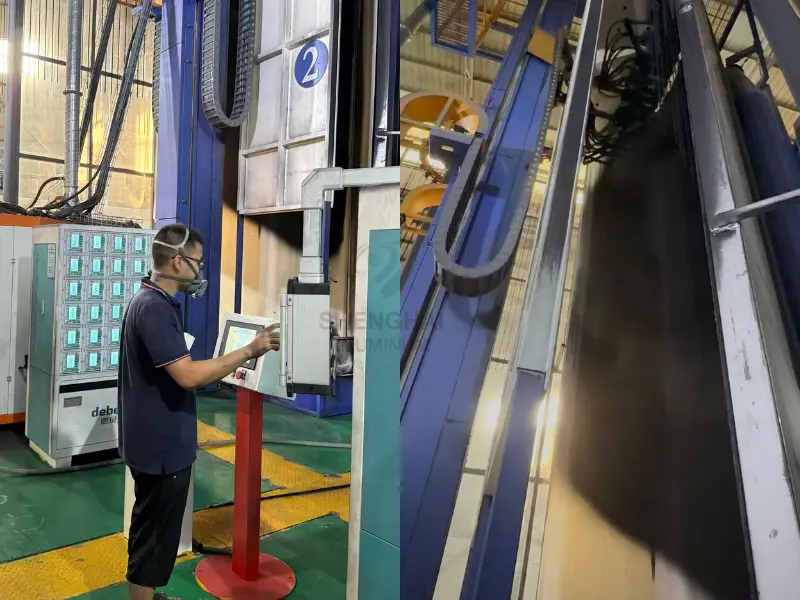

7. Spraying Line:

1) There are two types: horizontal and vertical. The vertical line has hanging holes, which improves profile surface leveling, particle removal, and surface adhesion.

2) Differences:

a. Labor Input: Vertical lines require approximately 50% less labor than horizontal lines.

b. Production capacity: 1,200 tons per month for vertical type and 400 tons per month for horizontal type.

c. Process: For the vertical type, it is loading, pretreatment, spraying, and unloading.

Horizontal type: upper row, pretreatment, lower row, upper row, spraying, lower row;

d. Equipment investment: approximately 7 million for the vertical line and about 1.4 million for the horizontal line. The investment for the vertical line is about five times that of the horizontal line.

E. Supplement: Thinner profiles are suitable for horizontal spraying.

8. Note:

1) The color codes, prices and production periods of the regular colors and non-regular colors.

2) Powder brand: domestic powder, imported powder (Austrian Tiger powder, Dutch Akzo powder), ordinary powder or metal powder, whether weather-resistant.

Why is powder coating applied to aluminium profiles?

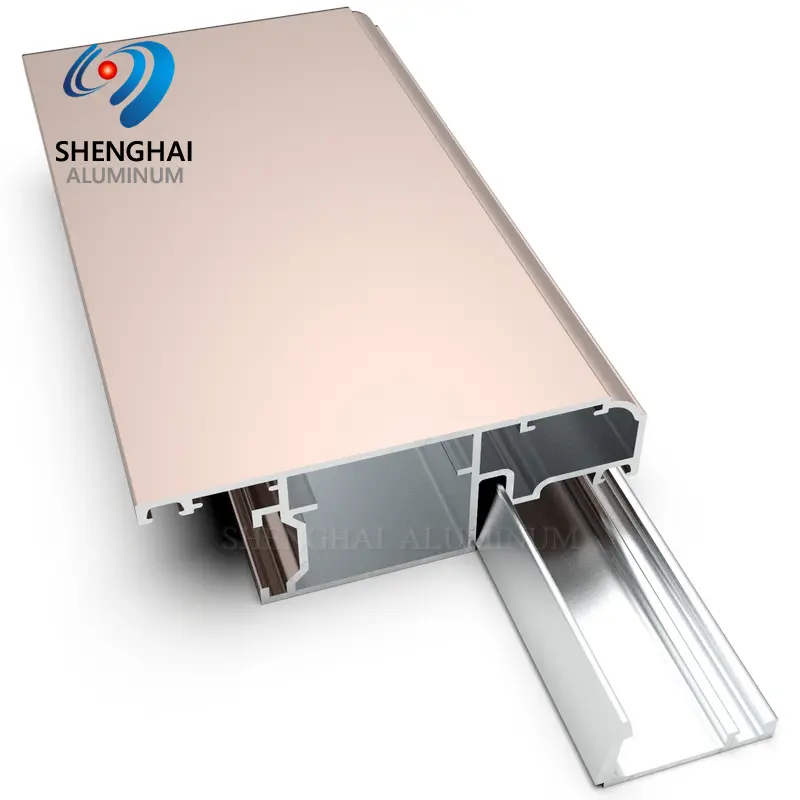

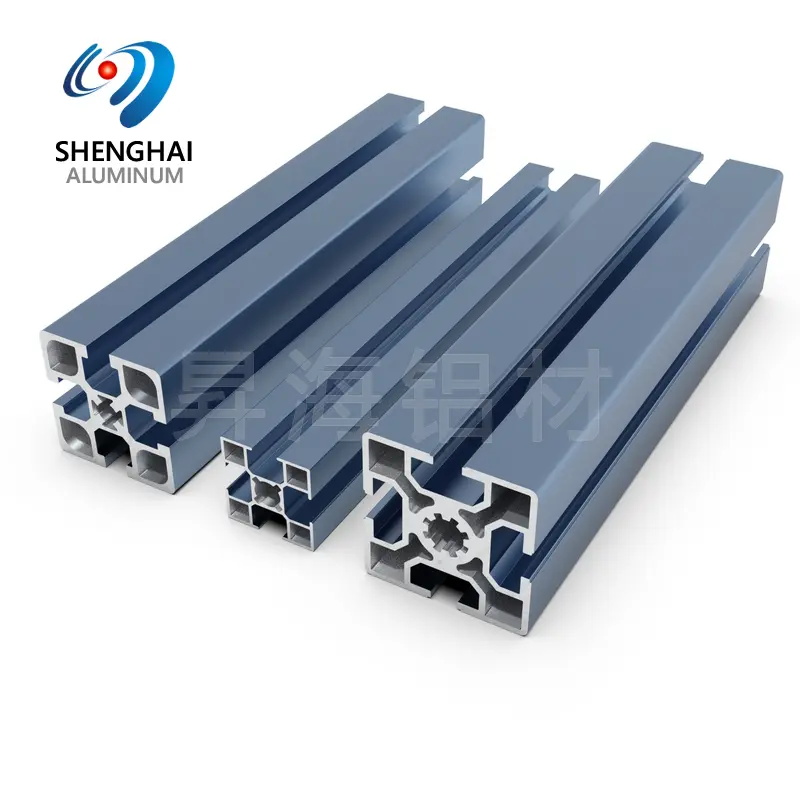

Powder coatings offer a variety of special effects for aluminum profiles. They provide a rich selection of colors and diverse texture decorations, thus meeting different design styles. Through heat transfer technology, powder coatings can achieve realistic wood grain textures, with clear patterns and vivid colors that penetrate into the coating interior, creating a unique visual effect. Moreover, powder coatings can completely cover the extrusion marks and flaws on the surface of aluminum profiles, enhancing the surface quality of the products. Choosing high-quality powder coatings can ensure adequate protection for the products.

aluminum profile powder coating process has the following significant advantages:

The process is relatively simple, mainly due to the improvement of the automatic precision of the main equipment in the production process. Some key technical parameters can now be controlled by microcomputers.

1.It effectively reduces the difficulty of process operation and significantly reduces the auxiliary equipment at the same time.

2. The yield rate is high. Generally speaking, if all measures are properly taken, the generation of non-conforming products can be controlled to the greatest extent.

3. Energy consumption is significantly reduced. In the ordinary anodic oxidation and electrophoretic coating production processes, the consumption of water and electricity is considerable, especially in the oxidation process. The output current of the rectifier can reach between 8,000 and 11,000 A, and the voltage is between 15 and 17.5 V. Coupled with the heat loss of the machine itself, continuous cooling with circulating water is required, and the electricity consumption per ton is often around 1,000 degrees. At the same time, the reduction of auxiliary facilities can also lower some electricity consumption.

4. The degree of pollution to water and the atmosphere is reduced. Caustic soda flakes, sulfuric acid and other liquid organic solvents

The discontinuation of its use not only reduces water and air pollution but also effectively enhances the competitiveness of aluminum profiles against plastic-steel profiles as environmentally friendly products, and correspondingly lowers some production costs.

5. The labor intensity of workers has been significantly reduced. Due to the adoption of automated assembly lines, the feeding method and fixtures have been improved.

The usage method has been significantly simplified, which has improved production efficiency and reduced labor intensity.

6. The surface quality requirements for the raw material have been significantly reduced. Powder coating can completely cover the extrusion lines on the surface of the profiles.To cover up some surface defects of aluminum profiles and improve the surface quality of finished aluminum profiles;

7.Some physical properties of the coating film, such as hardness, wear resistance and acid resistance, have been significantly improved compared with other surface treatment films, which can effectively extend the service life of aluminum profiles.

Where can I find a factory for aluminum profile powder coating process?

Shenghai is a manufacturer with 15 years of experience in aluminium profile production and 10 years of experience in powder coating technology. The technology is quite mature. If you come to us, we will provide you with a one-stop solution for aluminium extrusion.