Aluminum Anodizing Guide

Date: 2025-12-09Views: 234

Aluminum anodizing is a surface treatment method for aluminum profiles, completed through an electrochemical process. Its film thickness can be several times thicker than that of natural oxide films, thus significantly increasing corrosion resistance. The following is a detailed introduction to aluminum anodizing.

What is Aluminum Anodizing?

It is essentially an electrochemical surface treatment method. Using aluminum profiles as the anode material, it is placed in an acidic environment, and under the influence of an external electric current, a film "grows" on the surface of the aluminum profile. This film has the chemical formula Al₂O₃, and is known for its strong corrosion resistance.

Why is Aluminum Anodizing Necessary?

Corrosion Protection

Natural oxide films are thin and uneven, requiring a thicker layer of aluminum oxide for protection. The surface film of anodized aluminum is a dense layer of aluminum oxide, effectively preventing reactions with external environmental substances such as oxygen, water, and salt spray. Therefore, it resists salt spray environments and does not undergo chemical changes even in relatively humid environments over long periods, providing significant protection for aluminum profiles.

Enhancing Appearance Value

Pure aluminum has a relatively monotonous color, requiring a wider range of colors to suit various applications. Anodized aluminum films offer rich and varied colors, significantly improving the visual experience and enhancing the overall appearance and product value.

Increasing Hardness

Pure aluminum has low hardness, without surface treatment, its surface is easily scratched and worn, affecting its appearance. The oxide film further increases the surface hardness of aluminum alloy profiles.

Insulation Protection

While metals are hard, they are also conductive. Therefore, aluminum profiles need insulation to protect personal safety. The principle is that the structure of the aluminum oxide film, α-Al₂O₃, effectively prevents electron conduction, providing effective insulation protection when touched.

Easy-to-Clean Surface

The anodized film is very smooth. Even with dust, oil, and impurities, cleaning is easy, simple wiping is usually sufficient, reducing subsequent cleaning costs.

Aluminum Anodizing Steps:

Cleaning: To ensure the oxide film adheres evenly and smoothly to the aluminum profile, surface impurities need to be removed to guarantee the proper growth of the oxide film. Specific operations include surface polishing, degreasing, and dust removal.

Aluminum Anodizing: The aluminum profile is used as the anode, placed in an acidic solution, and subjected to direct current, causing aluminum oxide to gradually form on the aluminum surface. Factors affecting the oxide film thickness include temperature, current, voltage, and reaction time.

Cleaning: After the chemical reaction, some electrolyte residue remains on the aluminum profile. To prevent corrosion, the aluminum profile with the formed film needs to be cleaned using deionized water.

Coloring: This is divided into electrolytic coloring and dye dyeing. Electrolytic coloring produces color by depositing metal ions, resulting in a more stable color. Dye dyeing works by the porous oxide film adsorbing dye molecules, with the temperature controlled at around 50℃ and the time controlled at around ten minutes.

Sealing: Sealing involves placing the aluminum profile in a special sealing agent. The sealing agent fills the porous structure of the oxide film, thus ensuring its corrosion resistance.

What are the applications of aluminum anodizing?

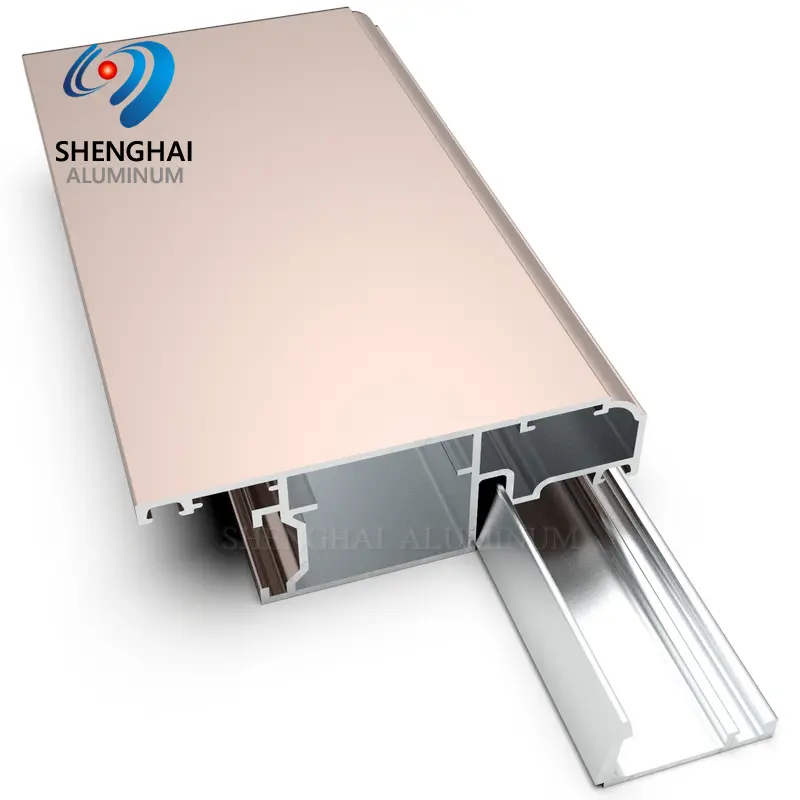

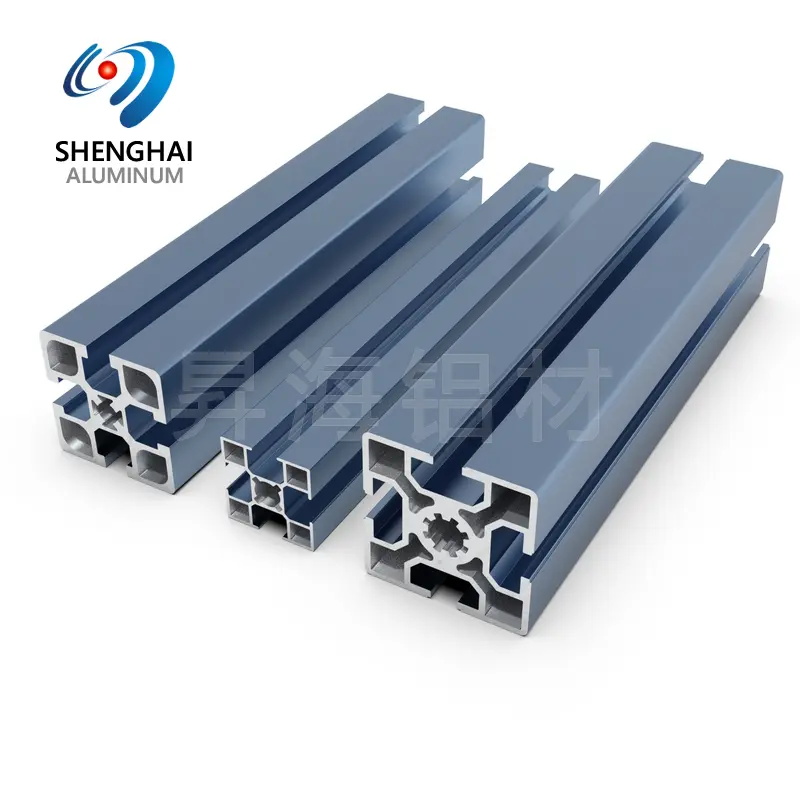

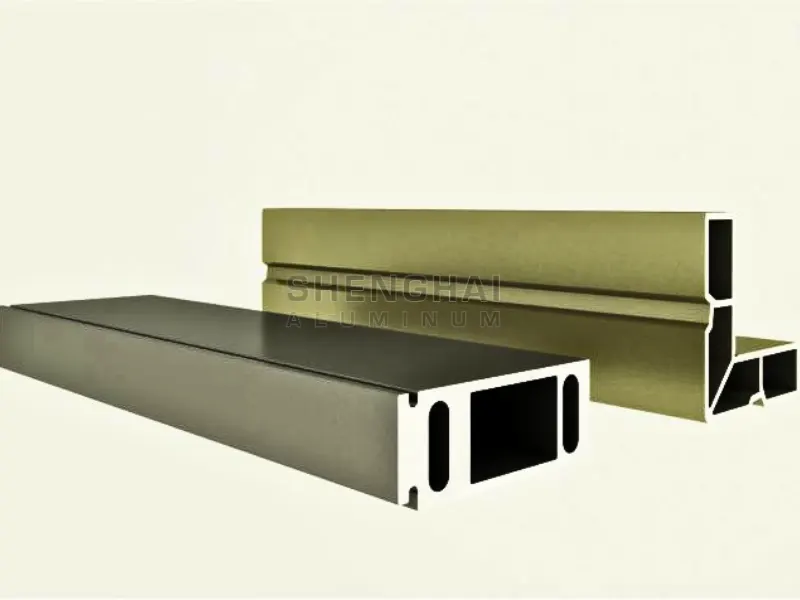

Anodizing has numerous applications in daily life, including electronic device casings, heat sinks, aluminum cabinets, aluminum door and window frames, curtain wall frames, and bicycle frames.

What are the differences between aluminum anodizing and aluminum powder coating in terms of Aluminum Finish?

Appearance

The oxide film from aluminum anodizing appears smooth and delicate with a slight sheen. However, the color is generally limited, including silver, copper, and black.

Powder coating has a rougher surface, somewhat like the feel of plastic. However, it offers a wider range of colors, up to 2000.

Protective Layer

The oxide film from aluminum anodizing is thinner, with only micron-level changes on the surface after formation, but it has significantly greater hardness than powder coating.

Abrasion Resistance

Anodizing has higher hardness, resulting in much better abrasion resistance than powder coating. Anodizing is mostly suitable for public places or environments with frequent scratches.

Corrosion Resistance

Corrosion resistance depends on the surface treatment parameters and environmental factors. Anodizing is better suited for extreme environments, while powder coating is better suited for everyday scenarios. Anodizing achieves the same high corrosion resistance as powder coating, but the former is more expensive. Each has its own advantages.

Why choose Shenghai Aluminum for aluminum anodizing?

Shenghai Aluminum has focused on aluminum profile production for 15 years. Our powder coating and anodizing processes are mature. Our annual sales of surface-treated aluminum profiles exceed US$80 million. We believe we can provide you with a one-stop aluminum extrusion solution.Please contact us for a quote.