Do you know what aluminum extrusion is?

Date: 2025-10-05Views: 12

Aluminum extrusion is a metal processing process that plastically deforms aluminum bars or aluminum alloys into profiles with specific cross-sectional shapes. This allows for customized shapes.

I. Classification of Aluminum Extrusion

Its classification is typically based on different dimensions, such as process parameters, product characteristics, die structure, or alloy type, to meet diverse technical requirements and product applications. The following are the most common classification methods.

1. Classification by Alloy:

Generally, there are pure aluminum extrusions, aluminum-manganese alloy extrusion, aluminum-magnesium alloy extrusion, etc.

2. Classification by Temperature:

Hot extrusion (usually 350-550°C), cold extrusion (≤150°C), and warm extrusion (150-350°C).

3. Classification by Die:

Flat die extrusion, conical die extrusion (flat-conical die), split die extrusion, and combination die extrusion.

4. Classification by Product Cross-sectional Shape:

Solid profile extrusion, hollow profile extrusion, and tube extrusion.

II. The methods for various extrusion types are similar. The following is an introduction to hot extrusion.

Core Material Preparation:

Generally divided into four categories: raw materials, die tools, consumable materials, and post-processing materials (surface treatment, machining, and testing materials).

General Extrusion Steps

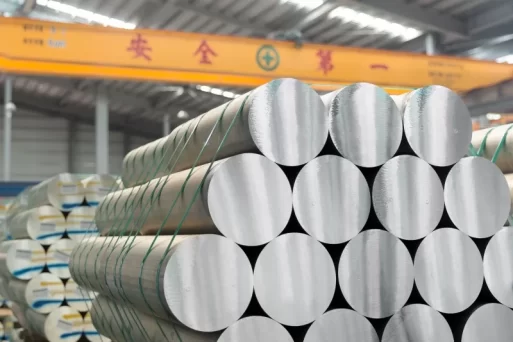

1. Casting Rod Preparation:

The raw material is generally 99% pure aluminum ingots. Solid aluminum rods are produced through smelting, alloying, and processing.

2. Heat Treatment:

The aluminum bar is heated to approximately 500°C to facilitate extrusion from the die.

3. Extrusion:

The heated aluminum bar is pushed into the extrusion machine, where strong pressure is applied to force the aluminum through the die. The die is made of high-strength steel to maintain its rigidity, allowing for highly precise extruded aluminum with a variety of shapes. The die determines the cross-sectional shape of the final product.

4. Cooling and Quenching:

After extrusion, the extruded aluminum must be cooled quickly. Slow cooling will increase the temperature difference between the surface and the core, further exacerbating thermal stresses and potentially causing deformation (such as bending and twisting) or cracking. Common cooling methods include air cooling and water cooling.

5. Ensuring Accurate Shape and Dimensions:

The cooled aluminum profile may exhibit slight warping, which can be straightened using specialized machines before being cut to desired lengths.

6. Surface Treatment and Further Processing:

Optional treatments include anodizing (for corrosion resistance and decorative effects), electrophoresis, and spray coating. Further machining (drilling, milling), and welding to form components are also possible.

III. Applications of Extruded Aluminum

Architecture

Door and Window Systems: Aluminum Alloy Doors and Windows

Building Structures: Roof Brackets, Sunroom Frames, Partition Systems

Decorative Materials: Skirting Boards, Edge Trims, Decorative Moldings

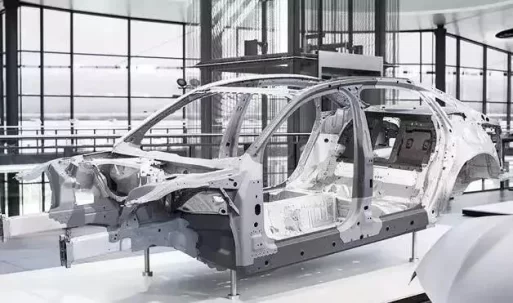

Transportation

Automotive: Body Frames, Radiators

Rail Transit: High-Speed Rail Car Frames, Subway Interiors

Aerospace: Aircraft Interior Structures, Luggage Compartment Frames

Electronic and Electrical Appliances

Heat Dissipation Devices: CPU Heat Sinks, LED Heat Sinks

Enclosure Structures: Electrical Casings, Chassis Frames, Equipment Brackets

Conductive Components: Busbars, Conductors Power strips

Industrial equipment

Mechanical equipment: Assembly line supports, workbench frames, guardrails

Automation systems: Robotic arms, conveyor belt supports

Energy equipment: Solar panels, wind turbine components

Household items

Furniture: Table and chair frames, cabinet profiles, display racks

Sports equipment: Trekking poles, bicycle racks, fitness equipment

Daily necessities: Ladders, trolley frames, luggage frames

Special applications

Military equipment: Lightweight weapon supports, equipment cases

Medical equipment: Wheelchair frames, medical equipment supports

IV. Why choose extruded aluminum?

1. Lightweight and high strength

Aluminum has a low density, only one-third that of steel. By alloying with magnesium, copper, and other materials, the strength of aluminum alloys can be increased to the same level as mild steel, offering a unique combination of lightness and high strength.

2. High customization

Products formed using the aluminum extrusion process are extremely diverse, and the process is simple. The desired shape can be formed directly into the mold without the need for secondary cutting.

3. Corrosion Resistance

Aluminum's surface easily forms an oxide film, preventing it from reacting with water and air. It can also undergo strengthening treatments such as anodizing, electrophoresis, and powder coating, significantly increasing its corrosion resistance by up to 10 times. After oxidation, it can withstand up to 30 years of use in marine climates without fading or corrosion.

4. Environmentally Friendly

100% Recyclable: Remelting extruded aluminum scrap consumes only 5% of the energy required to produce primary aluminum, resulting in a recycling rate exceeding 95%, complying with EU RoHS Directives and LEED green building certification requirements.

Low Carbon Emissions: Compared to steel, bauxite production consumes only half the energy required to produce it, contributing to global environmental goals.

Now, do you understand what aluminum extrusion is?