How Multi-Chamber Aluminum Window Profiles Improve Energy Efficiency and Durability

When choosing doors and windows for residential or commercial projects, more than just aesthetics matter. Performance, energy savings, and long-term reliability are increasingly becoming top priorities. That’s where multi-chamber aluminum window profiles come into play—offering a smart structural solution for both beauty and function.

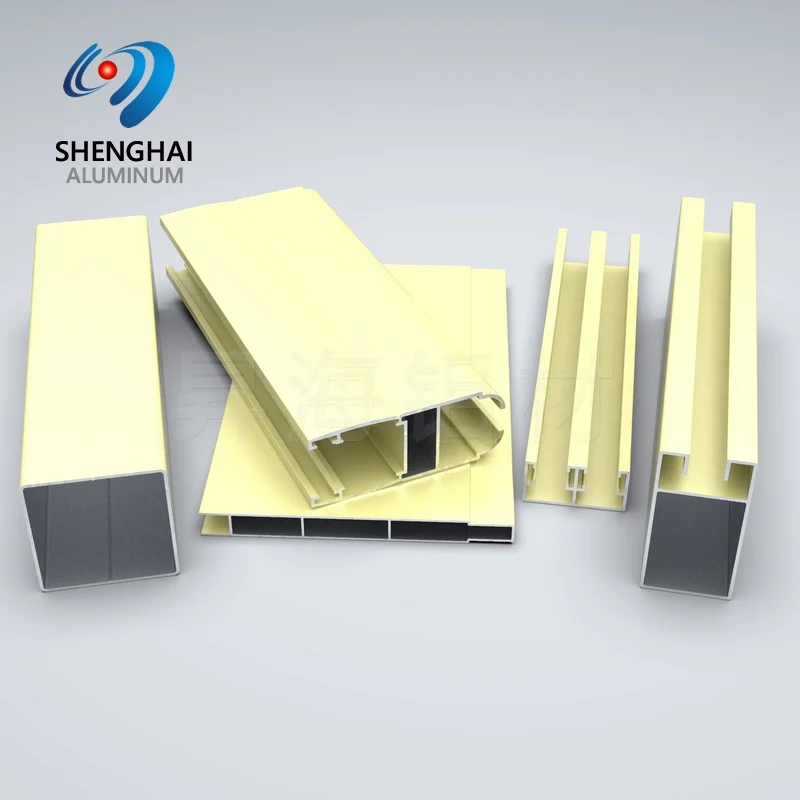

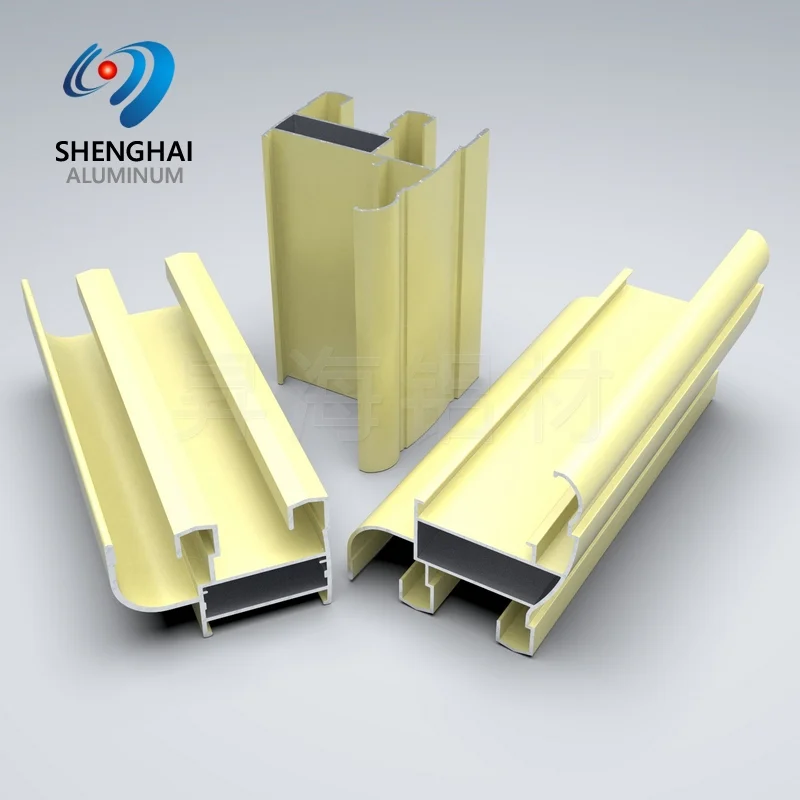

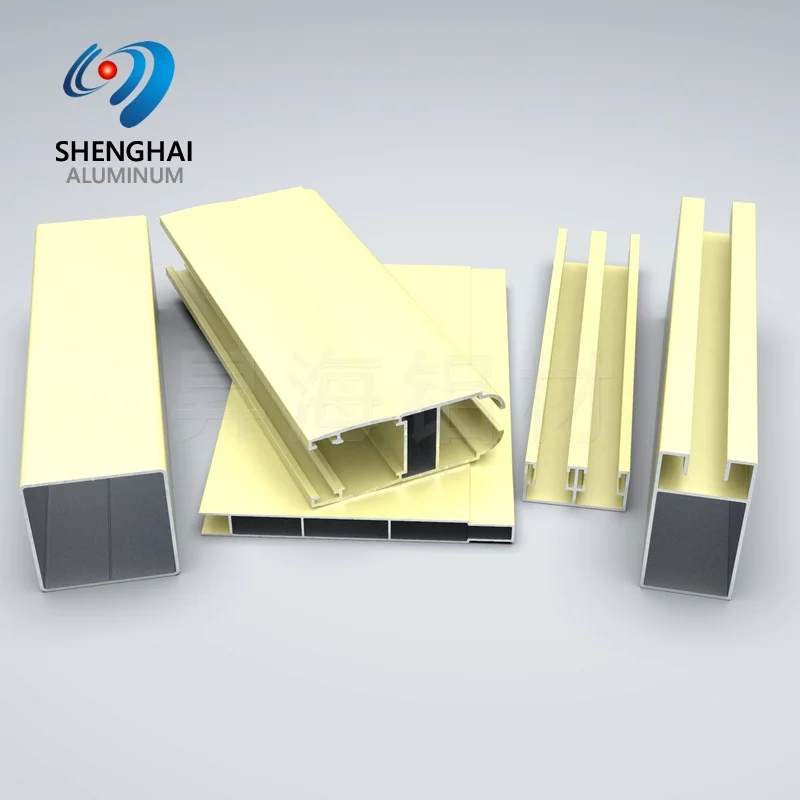

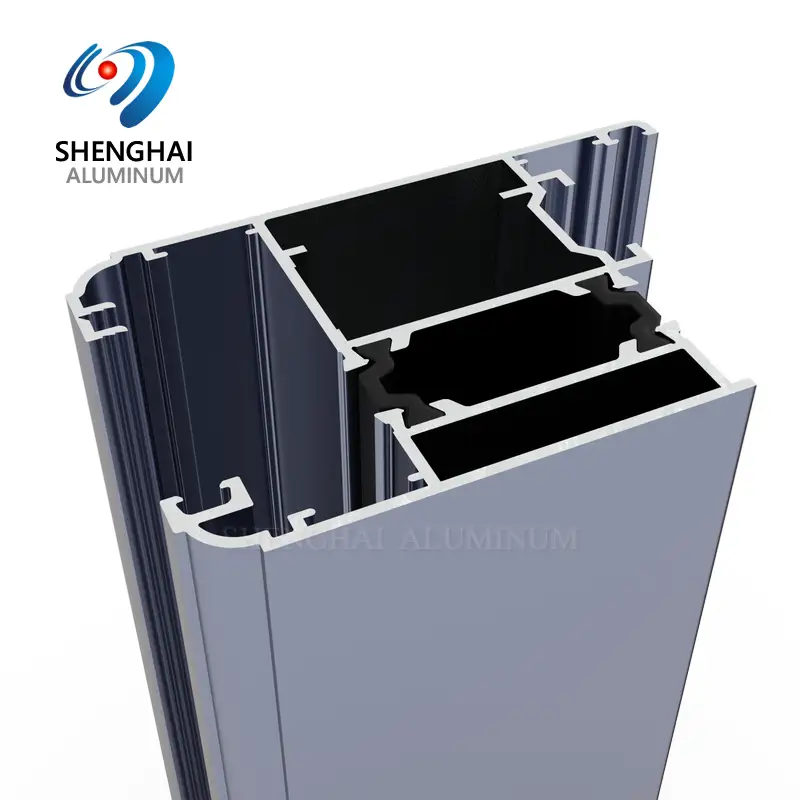

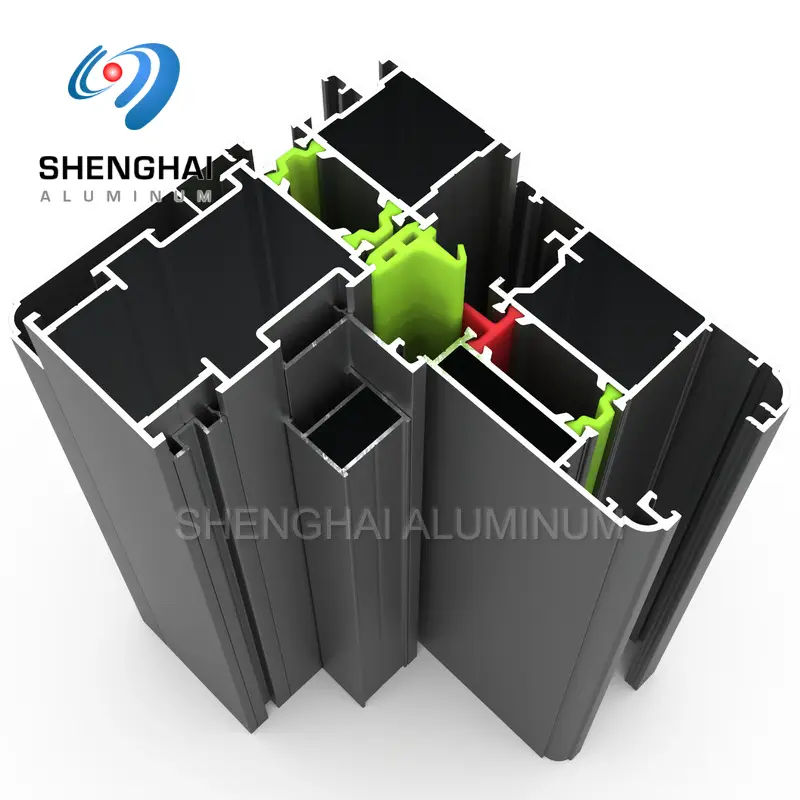

What Is a Multi-Chamber Aluminum Window Profile?

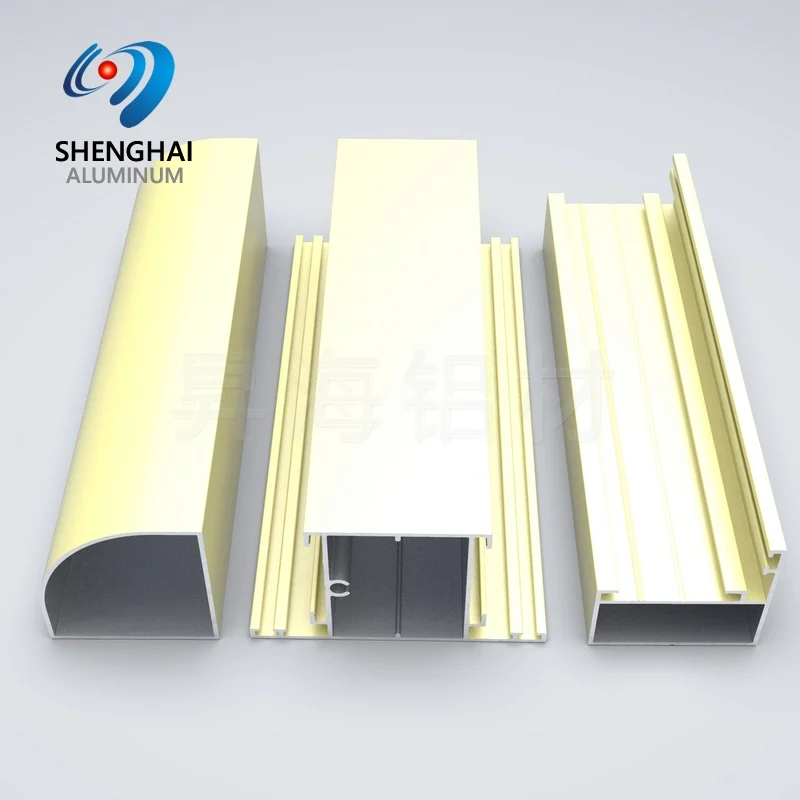

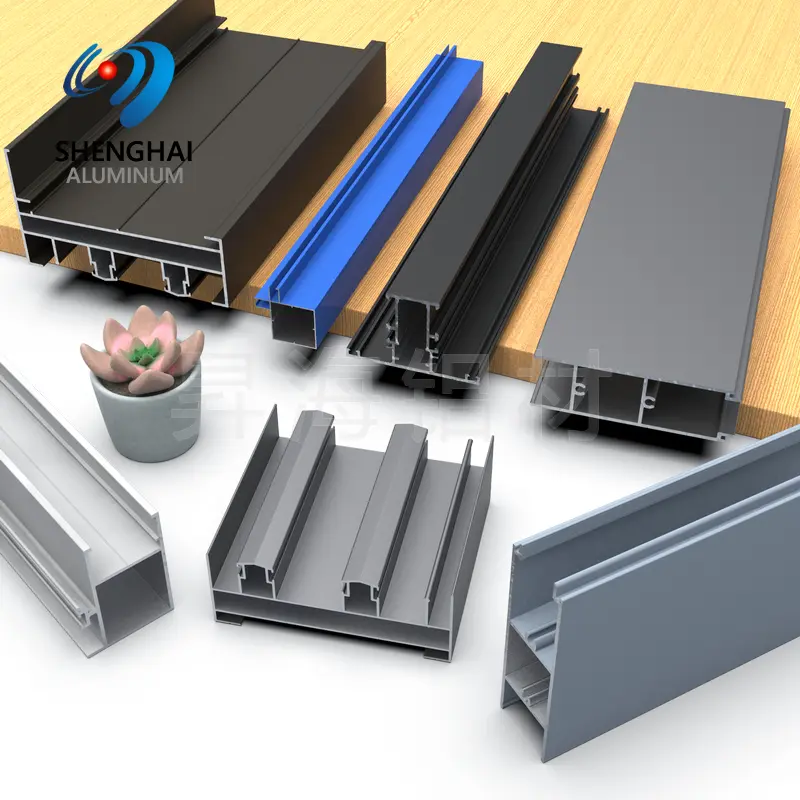

A multi-chamber aluminum profile features internal cavities (air chambers) created during the extrusion process. These chambers act as insulation buffers and structural reinforcements, significantly improving the window’s overall performance. Depending on the design, profiles may have three, five, or even seven chambers, each serving a specific function like supporting hardware, enhancing insulation, or improving water drainage.

Key Benefits of Multi-Chamber Structures

1. Superior Thermal Insulation

The multiple air cavities within the profile act as natural thermal barriers. Combined with thermal break technology, this structure minimizes heat loss in winter and heat gain in summer, reducing energy bills and improving indoor comfort.

2. Enhanced Soundproofing

Multi-chamber profiles help absorb and block external noise. Whether it’s traffic, construction, or neighborhood activity, these profiles significantly improve acoustic insulation—making them ideal for urban environments.

3. Increased Structural Strength

Internal chambers act as reinforcements, distributing stress evenly across the profile. This makes multi-chamber aluminum frames more resistant to deformation, especially under high wind loads, making them perfect for high-rise buildings or wide-span sliding doors.

4. Efficient Drainage and Sealing

Some chambers are specifically designed to create independent water drainage paths, reducing the risk of water infiltration during heavy rain or storms.

Choosing the Right Aluminum Alloy

For optimal results, 6063-T5 aluminum alloy is the most commonly used material in window and door systems. Known for its excellent surface finish, corrosion resistance, and good strength-to-weight ratio, it’s ideal for extruding complex multi-chamber designs.

For larger frames or load-bearing requirements, higher strength alloys like 6061-T6 or 6082 can be considered. These alloys provide additional structural support, especially for curtain walls, sunrooms, or commercial storefronts.

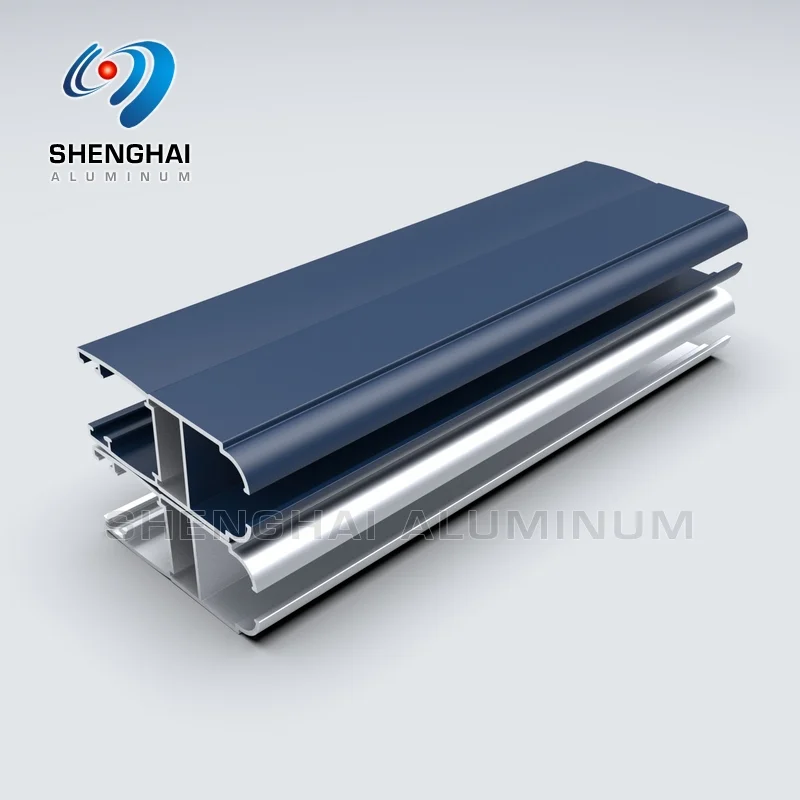

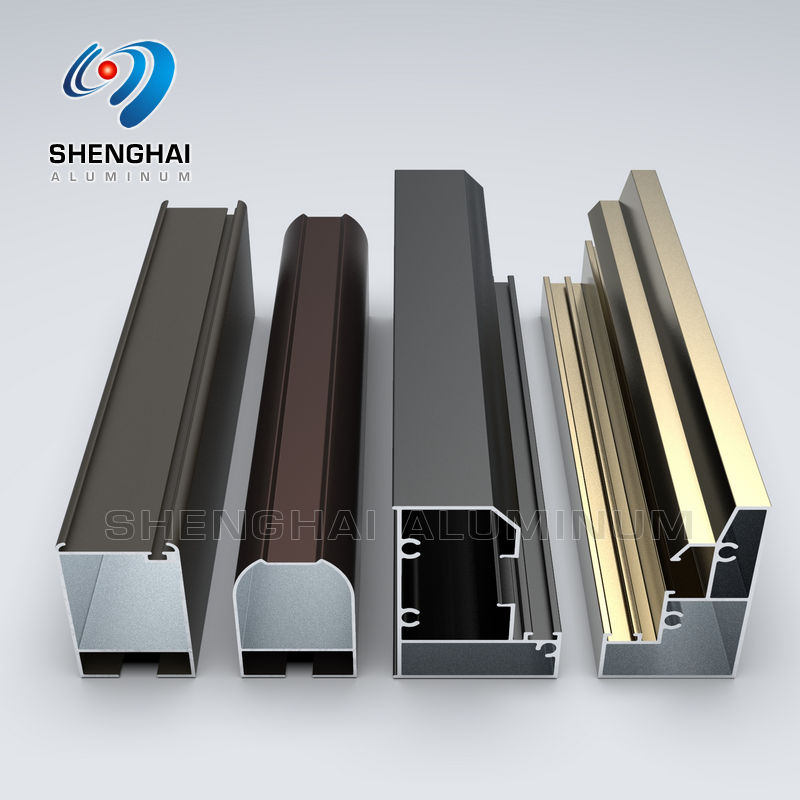

Surface Treatments that Extend Longevity

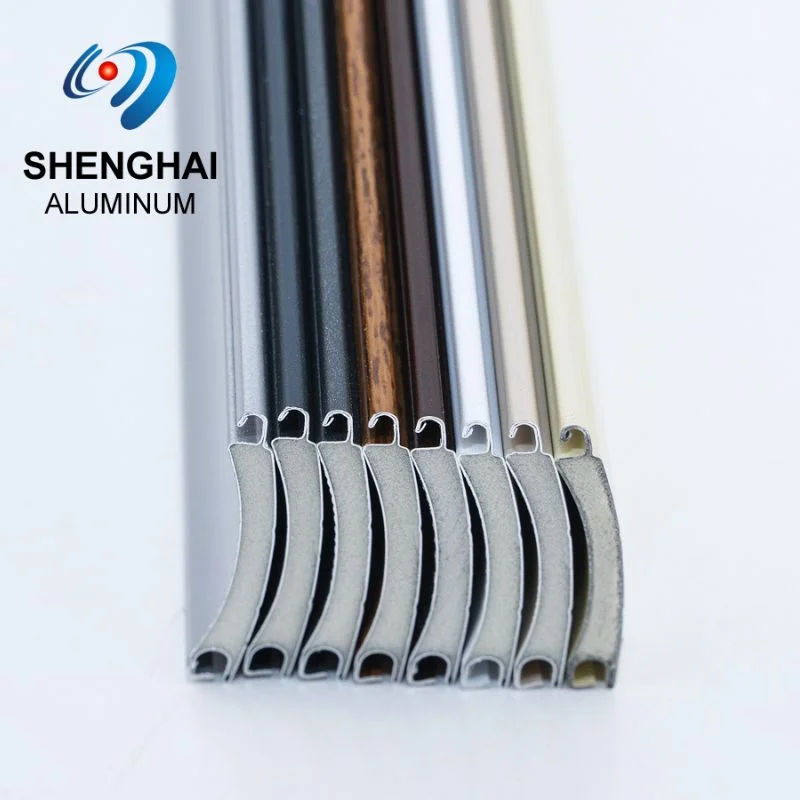

The surface finish of aluminum windows not only affects aesthetics but also contributes to longevity and weather resistance. Common treatments include:

-

Anodizing – Durable, corrosion-resistant, and available in metallic finishes

-

Powder Coating – Offers color variety and UV resistance

-

Wood Grain Transfer – Combines aluminum strength with natural wood appearance

-

Electrophoretic Coating – High gloss, smooth feel, and excellent adhesion

With the right aluminum alloy and surface finish, your doors and windows will not only look premium but also withstand harsh climates for years.

Applications in Modern Architecture

Multi-chamber aluminum window profiles are widely used in:

-

Luxury villas and smart homes

-

High-rise apartment buildings

-

Office buildings and commercial facades

-

Energy-efficient renovations and green building projects

Their ability to combine form and function makes them the go-to choice for modern construction.

Multi-chamber aluminum profiles offer a future-proof solution for architects, builders, and homeowners who demand performance and elegance. By choosing the right aluminum material, chamber design, and surface finish, you ensure your doors and windows deliver thermal comfort, noise control, and durability for years to come.

Our Materials:

Our customers from all over the world: